Unlocking the Future of Cryogenic Technology: The Essential Role of Cryogenic Valves

Cryogenic valves play a crucial role in the advancement of cryogenic technology, which has become increasingly significant across various industries, including aerospace, medical, and energy sectors. According to a recent industry report by MarketsandMarkets, the global cryogenic valve market is projected to reach USD 5.8 billion by 2026, growing at a CAGR of 5.3% during the forecast period. This growth is driven by the rising demand for cryogenic applications, particularly in liquefied natural gas (LNG) production and storage. As these technologies evolve, the importance of specialized cryogenic valves, capable of handling extreme temperatures and pressures, cannot be understated. These components not only ensure safety and reliability but also enhance the efficiency of cryogenic systems. Understanding the intricacies involved in selecting and maintaining cryogenic valves is essential for professionals aiming to leverage this cutting-edge technology in their operations.

The Importance of Cryogenic Valves in Advanced Technology Applications

Cryogenic valves play a critical role in the application of advanced technologies, particularly in industries such as aerospace, medical, and energy production. According to a recent report by ResearchAndMarkets, the global cryogenic valve market is projected to reach USD 5.61 billion by 2027, with a compound annual growth rate (CAGR) of 4.2% from 2020 to 2027. This growth is driven by the increasing demand for liquefied gases and their applications, which underscores the necessity of reliable and efficient cryogenic valves.

The importance of cryogenic valves extends to their ability to withstand extreme temperatures and pressures essential for the safe handling of liquefied natural gas (LNG) and other cryogenic fluids. For example, the American Cryogenics Association highlights that cryogenic systems often operate at temperatures below -150°C, where standard valves fail to perform adequately. Additionally, in the aerospace sector, cryogenic valves are essential for the propulsion systems of next-generation spacecraft, as evidenced by NASA’s Artemis program, which relies on these specialized valves for its liquid oxygen systems. The performance and reliability of cryogenic valves are pivotal not only for operational efficiency but also for ensuring safety in these advanced technology applications.

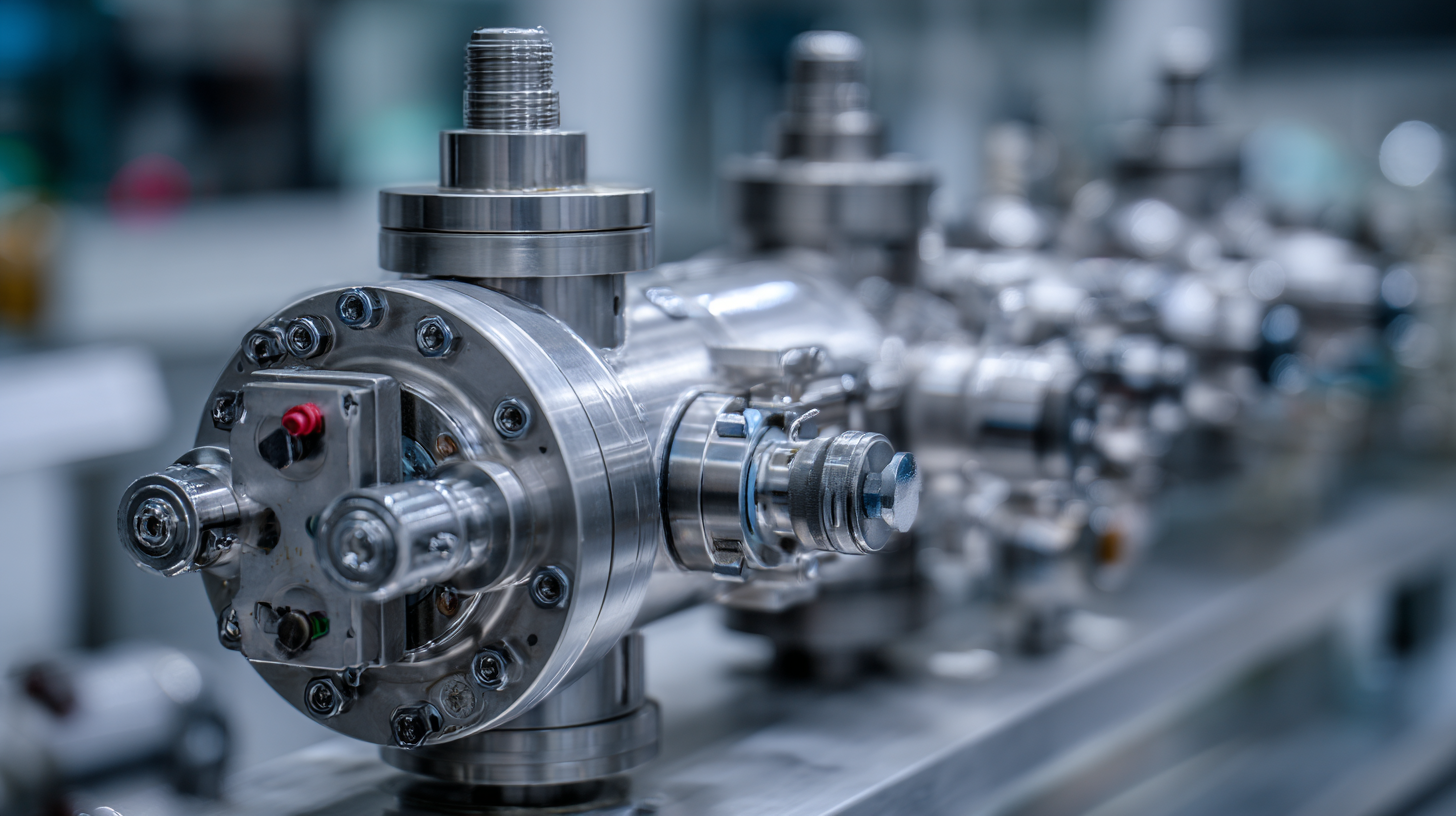

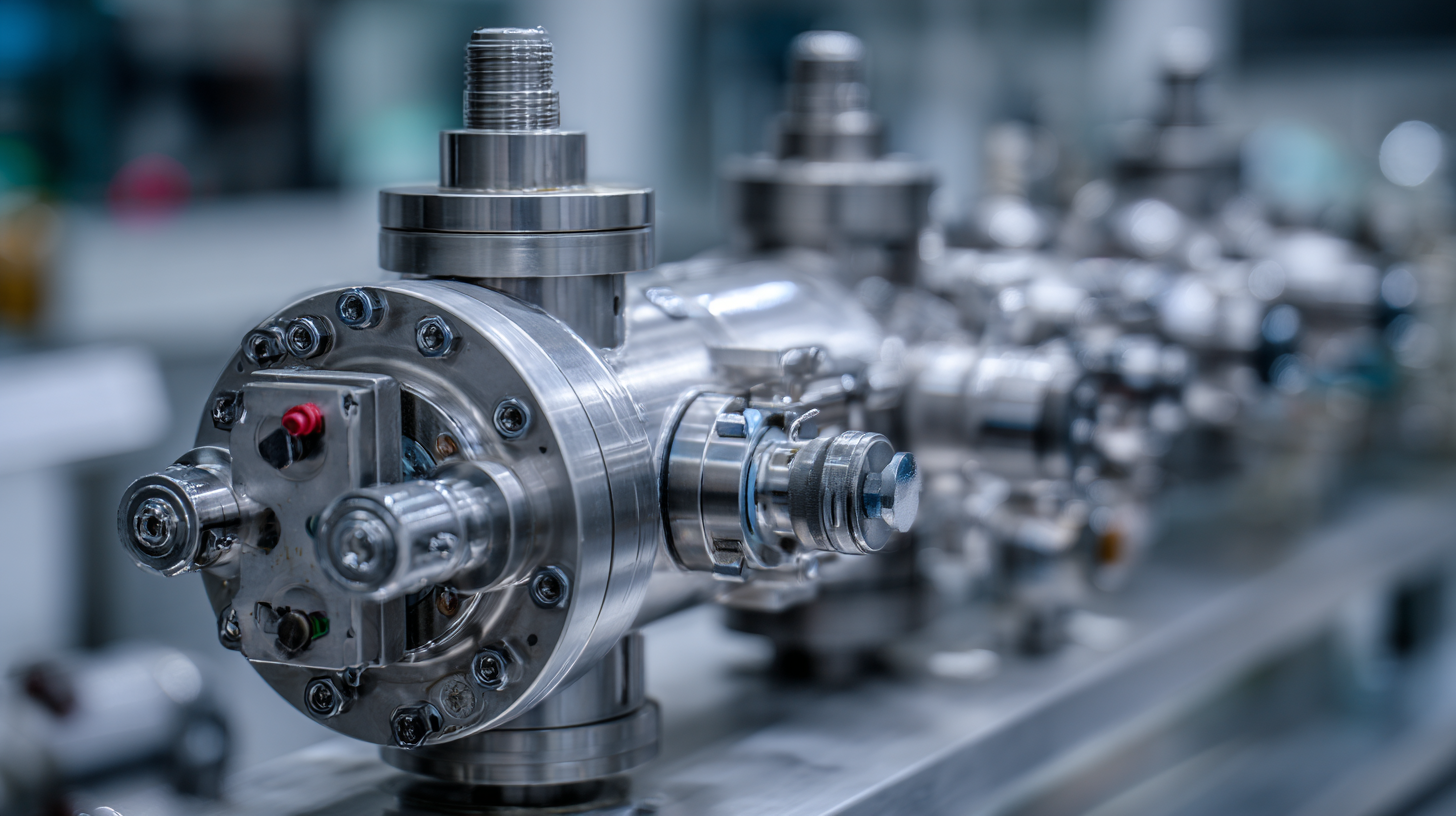

Key Features to Look for in High-Performance Cryogenic Valves

Cryogenic valves play a crucial role in the safe and efficient operation of cryogenic systems, particularly in industries dealing with liquefied natural gas (LNG) and advanced cooling technologies. When selecting high-performance cryogenic valves, key features to consider include their ability to withstand extreme temperatures—often below -162°C for LNG applications—and the materials used in their construction, which must ensure durability and resistance to thermal fatigue.

Furthermore, the design of cryogenic valves should facilitate easy maintenance and provide reliable sealing to prevent leaks. As the global cryogenic equipment market is projected to grow significantly, understanding these essential features will help industries achieve greater performance and ensure safety in their operations. With advancements in cryogenic technology, such as recent breakthroughs in large-scale cooling systems, the demand for innovative and efficient cryogenic valves will continue to rise.

Best Practices for Maintaining Cryogenic Valves to Ensure Longevity

Proper maintenance of cryogenic valves is critical to ensuring their longevity and reliability in various applications, particularly in industries such as aerospace, healthcare, and energy. Regular inspections should be conducted to identify any signs of wear or damage. This includes checking for leaks, ensuring that seals and packing are intact, and verifying that the valve actuators operate smoothly. Implementing a routine maintenance schedule helps catch potential issues before they lead to failures, thereby reducing downtime and maintaining the integrity of the cryogenic system.

Additionally, using appropriate cleaning methods is essential for maintaining cryogenic valves. Contaminants can compromise valve performance, so employing specialized solvents that are compatible with cryogenic materials is advisable. Furthermore, it is crucial to avoid introducing moisture during the maintenance process, as water can freeze and cause blockages or damage within the valve. Training personnel in best practices for handling and maintaining these delicate components will significantly contribute to their performance and lifespan, ultimately unlocking the potential of cryogenic technology.

Unlocking the Future of Cryogenic Technology: The Essential Role of Cryogenic Valves

| Aspect |

Details |

Best Practices for Maintenance |

| Material Type |

Stainless Steel, Brass, Monel |

Regularly inspect for corrosion |

| Temperature Range |

-196°C to +150°C |

Calibrate regularly to ensure accuracy |

| Pressure Ratings |

Up to 3,000 psi |

Monitor during operation for leaks |

| Common Applications |

LNG, Industrial Gas, Medical |

Perform routine cleaning and testing |

| Failure Modes |

Leakage, Freezing, Mechanical Wear |

Schedule preventative maintenance |

Innovative Trends in Cryogenic Valve Design for Future Developments

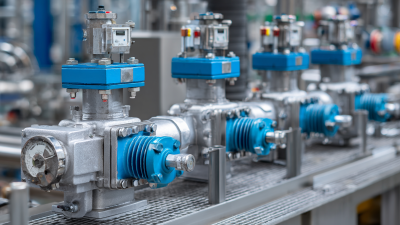

As the demand for cryogenic technology continues to rise, the design of cryogenic valves has evolved to meet new challenges and opportunities. Innovative trends in this field focus on enhancing the efficiency and reliability of valve systems. Advanced materials are being utilized to withstand extreme temperatures and pressures, allowing for improved performance and durability. Additionally, the integration of smart technologies provides real-time monitoring and control, making it easier to manage complex cryogenic processes.

Another significant trend is the emphasis on modular design, which offers greater flexibility and ease of maintenance. This approach simplifies the installation and replacement of components, reducing downtime and operational costs. Furthermore, companies are investing in sustainable practices, developing cryogenic valves that minimize energy consumption and environmental impact. These advancements not only pave the way for future developments in various industries, such as aerospace and liquefied natural gas, but also position cryogenic valves as critical elements in the broader context of technological innovation and energy efficiency.

Safety Considerations When Working with Cryogenic Systems and Valves

When working with cryogenic systems and valves, safety considerations are paramount. Cryogenic temperatures, which can reach as low as -196 degrees Celsius, pose significant risks such as frostbite, asphyxiation, and equipment failure. Proper handling procedures must be adhered to, including the use of insulated gloves and face shields to protect the skin and eyes from the extreme cold. Personnel must be trained to recognize the signs of a cryogenic leak and to respond swiftly and effectively to mitigate hazards.

Moreover, the selection and maintenance of cryogenic valves are critical to ensuring safety in these systems. Valves must be specifically designed for low temperatures and high pressures, featuring materials that can withstand such conditions without becoming brittle. Routine inspections should be conducted to check for signs of wear, seal integrity, and proper function. Implementing a robust maintenance schedule can help prevent leaks and unexpected failures, thus ensuring that the system operates within safe parameters. Educating all personnel involved in the operation of cryogenic systems about these safety protocols is essential for minimizing risk and ensuring a secure working environment.

Temperature and Pressure Ranges in Cryogenic Systems