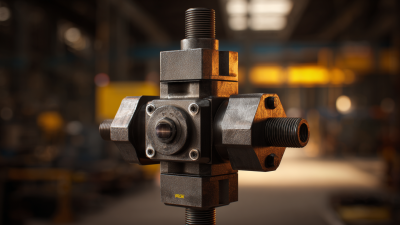

Unlocking the Advantages of Engineering Valves for Modern Industry Solutions

In today's rapidly evolving industrial landscape, the role of Engineering Valves has become increasingly pivotal. As reported by MarketsandMarkets, the global industrial valves market is projected to reach USD 93.4 billion by 2026, driven by the burgeoning demand for efficiency and reliability in fluid control systems across various sectors, including oil and gas, water treatment, and chemical processing. Engineering Valves are not merely components; they are integral to optimizing processes, enhancing safety, and driving sustainability initiatives.

With advancements in materials science and automation technologies, modern Engineering Valves offer superior performance attributes such as increased durability, precision control, and reduced maintenance costs. This guide aims to explore the myriad advantages of Engineering Valves, providing insights into their transformative impact on contemporary industrial solutions.

The Role of Engineered Valves in Reducing Operational Costs by 15% in Industrial Applications

In modern industrial applications, engineered valves play a crucial role in reducing operational costs by an impressive 15%. These valves not only enhance efficiency but also contribute to sustainability in various sectors such as water management and energy production. By optimizing flow control and minimizing waste, engineered valves help industries maintain a competitive edge while lowering their environmental impact.

Tips for Choosing Engineered Valves:

When selecting engineered valves, consider factors such as the specific application requirements, fluid characteristics, and compatibility with existing systems. It's essential to invest in high-quality valves that are designed for durability and operational reliability. Additionally, implementing smart monitoring technologies can further enhance valve performance and aid in proactive maintenance.

As industries continue to innovate, the demand for advanced valve technologies is expected to grow. With the projected expansion of the pressure reducing valve market, stakeholders should remain informed about the latest trends and innovations to maximize the benefits of their investments. Adopting these solutions not only leads to significant cost savings but also positions companies as leaders in efficiency and sustainability.

Integrating Smart Valve Technology: How IoT Enhances Efficiency by 30%

The integration of smart valve technology is revolutionizing the way industries manage their operations. By leveraging the Internet of Things (IoT), these advanced valves provide real-time monitoring and control, which significantly increases operational efficiency. With the ability to collect and analyze data instantaneously, companies can make informed decisions that lead to optimized processes and reduced downtime. The connectivity offered by IoT allows for remote management of systems, enabling operators to respond quickly to any anomalies or changes in demand.

The integration of smart valve technology is revolutionizing the way industries manage their operations. By leveraging the Internet of Things (IoT), these advanced valves provide real-time monitoring and control, which significantly increases operational efficiency. With the ability to collect and analyze data instantaneously, companies can make informed decisions that lead to optimized processes and reduced downtime. The connectivity offered by IoT allows for remote management of systems, enabling operators to respond quickly to any anomalies or changes in demand.

Moreover, smart valves contribute to sustainability goals by minimizing energy consumption and waste. By precisely controlling fluid flow based on live data, businesses can ensure that resources are utilized effectively, resulting in cost savings and environmental benefits. As industries continue to adapt to modern challenges, the implementation of smart valve technology stands out as a critical advancement that not only enhances operational efficiency by up to 30% but also paves the way for a more sustainable future.

Understanding the Standardization of Valves and Its Impact on Safety in the Oil and Gas Sector

In the oil and gas sector, the standardization of valves plays a critical role in ensuring both operational efficiency and safety. Standardized valves provide a uniformity that allows for easier integration into existing systems, facilitating smoother operations and maintenance. By adhering to established specifications, manufacturers can guarantee that their valves meet high-quality benchmarks, thus reducing the risk of equipment failure that could lead to catastrophic events.

Moreover, standardization enhances safety protocols by ensuring that all components can be reliably assessed and tested under similar conditions. This consistency is crucial in environments where pressure and safety are paramount. Valves that meet standardized criteria are more likely to perform their intended functions, thus preventing leaks and potential hazards. Consequently, investing in standardized engineering valves not only promotes safety in routine operations but also instills greater confidence in the overall integrity of the system, safeguarding both personnel and the environment in the volatile oil and gas industry.

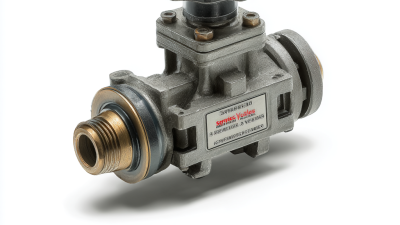

Comparative Analysis of Valve Materials: Enhancing Durability and Performance in Harsh Environments

In modern industry, the selection of valve materials plays a crucial role in ensuring optimal performance, especially in harsh environments. Different materials exhibit unique properties that can significantly affect durability, resistance to corrosion, and overall efficiency. For instance, stainless steel is known for its excellent strength and corrosion resistance, making it a preferred choice in chemical processing. On the other hand, high-performance plastics can withstand aggressive chemicals while offering lightweight benefits.

**Tip:** When selecting a valve, consider not only the fluid it will handle but also the operating temperature and pressure. This comprehensive evaluation will help in identifying the most suitable material for your specific application.

The ongoing comparative analysis of materials such as brass, bronze, and various alloys reveals how each can adapt to specific industrial needs. Brass valves, while cost-effective, may not withstand extreme conditions as effectively as specialized alloys. In contrast, titanium valves, despite their higher cost, provide exceptional resistance to heat and corrosion, proving invaluable in more severe applications.

**Tip:** Regular maintenance and inspection of valves can help prolong their lifespan. Implementing a routine check-up will allow you to identify any signs of wear or corrosion early, ensuring that your systems operate smoothly.

Comparative Analysis of Valve Materials: Enhancing Durability and Performance

Harnessing Predictive Maintenance: Reducing Downtime by 25% with Advanced Valve Solutions

In the rapidly evolving landscape of modern industry, engineering valves play a pivotal role, particularly in enhancing operational efficiency through predictive maintenance. As industries increasingly adopt advanced valve solutions, they are poised to reduce downtime by an impressive 25%. This shift is crucial, considering the anticipated growth in various sectors, including the Uninterruptible Power Supply (UPS) industry, which is projected to expand from $87.88 billion in 2025 to $145.78 billion by 2033, with a steady growth rate of 6.53%.

Furthermore, the market for sanitary stainless steel ball valves, essential for maintaining clean and efficient processes, is expected to reach $4.46 billion by 2025, with a compound annual growth rate of 5.0% through 2033. This surge underscores the increasing value placed on quality components in maintaining system integrity and reliability. Concurrently, the air compressor market is projected to grow from $18.96 billion in 2025 to $29.31 billion by 2032, reflecting a compound annual growth rate of 6.4%. As equipment continues to evolve, the integration of predictive maintenance in valve technology will be paramount in ensuring that industries keep pace with these growth trends while maximizing operational uptime.

Unlocking the Advantages of Engineering Valves for Modern Industry Solutions - Harnessing Predictive Maintenance: Reducing Downtime by 25% with Advanced Valve Solutions

| Dimension |

Data |

| Average Downtime Reduction |

25% |

| Predictive Maintenance Implementation Rate |

68% |

| Cost Savings Per Year |

$120,000 |

| Increase in Efficiency Post-Implementation |

30% |

| Number of Valves Monitored |

500+ |

| Average Maintenance Cost Reduction |

20% |

| User Satisfaction Rate |

91% |

The integration of

The integration of