Ultimate Guide to Understanding Bleed Valves for Global Buyers

In the realm of industrial applications, understanding the functionality and significance of a Bleed Valve is crucial for global buyers seeking optimal performance and reliability in their systems. As a key component in fluid control, bleed valves serve a vital purpose, allowing for the release of trapped air or gases, thereby maintaining the efficiency and safety of various processes. This ultimate guide aims to provide an in-depth exploration of bleed valves, covering essential aspects such as their design, operational principles, and application across different industries. Whether you are a seasoned professional or a newcomer, this comprehensive resource equips you with the knowledge needed to make informed decisions regarding bleed valves, ensuring you select the best options suited to your specific needs and requirements.

Join us as we delve into the complexities and nuances of bleed valves, empowering you to navigate the global marketplace with confidence.

Key Features of Bleed Valves You Should Know

Understanding bleed valves is essential for global buyers seeking efficient industrial solutions. These valves play a critical role in maintaining system safety and functionality, particularly in preventing pressure build-up and ensuring proper drainage. Key features of bleed valves include their ability to permit the controlled release of fluids, thereby safeguarding equipment from potential damage. A well-designed bleed valve can handle various media and withstand harsh operational conditions, which significantly contributes to the overall reliability of a system.

According to industry reports, the global bleed valve market is expected to witness substantial growth, driven by the expanding demand in sectors such as oil and gas, chemical processing, and water management. Innovations in materials and engineering designs are enhancing the performance and longevity of bleed valves. Buyers should pay attention to specifications such as maximum pressure ratings, temperature ranges, and compatibility with different fluids, as these factors directly influence operational efficiency. Investing in high-quality bleed valves can lead to reduced maintenance costs and improved system uptime, making them a vital component in any industrial setup.

Understanding Key Features of Bleed Valves

Common Types of Bleed Valves and Their Applications

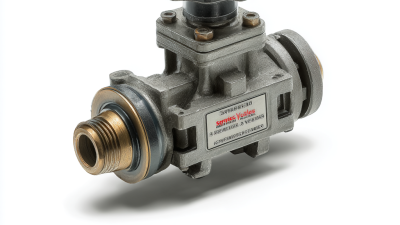

Bleed valves play a critical role in various industrial applications by managing the release of pressure or fluid from systems. Understanding the common types of bleed valves and their specific applications can significantly enhance operational efficiency and safety. The most frequently encountered types include manual bleed valves, automatic bleed valves, and self-venting bleed valves. Each of these variants serves distinct functions tailored to specific system requirements.

Manual bleed valves are often used in maintenance scenarios, allowing operators to manually release unwanted air or fluid. These valves are essential in hydraulic and pneumatic systems, where air pockets can lead to performance issues. On the other hand, automatic bleed valves function without operator intervention, making them ideal for applications requiring constant pressure management, such as in heating systems or water supply networks. Self-venting bleed valves combine the features of both, providing an efficient solution for high-demand systems by automatically venting excess pressure while maintaining optimal operational levels. Understanding these types and their applications is crucial for global buyers looking to tailor solutions for their specific needs.

Essential Specifications to Consider When Sourcing Bleed Valves

When sourcing bleed valves, it’s crucial to understand the essential specifications that cater to your specific needs. The first key specification is the valve material. Many bleed valves are made from materials like stainless steel, brass, or plastic, each catering to different environments and chemical compatibilities. Ensuring you select a valve made from the right material can significantly enhance its durability and performance in your system.

Another critical aspect to consider is the pressure rating of the bleed valve. It's vital to select a valve that can handle the maximum pressure of your application. Always check the manufacturer’s specifications for the maximum allowable working pressure to avoid potential failures in high-stress environments.

**Tip:** Always consult with a qualified engineer or supplier to determine the right specifications for your application. Fully understanding the required dimensions, connection types, and operation methods can save you considerable time and costs down the line.

Additionally, don’t overlook the importance of the valve operation type—manual, automatic, or solenoid-operated options can vastly alter functionality and ease of use. Assess your project requirements carefully to choose the most suitable operation type for efficient and effective bleed valve performance.

Tips for Evaluating Quality and Performance of Bleed Valves

When evaluating the quality and performance of bleed valves, several critical factors must be considered. According to a report by the International Society of Automation, improperly functioning bleed valves can lead to process inefficiencies and increased operational costs, sometimes exceeding 20% of a facility’s annual budget. Hence, assessing materials used in the manufacture of bleed valves is essential; they should be corrosion-resistant and suitable for the specific operating conditions.

Furthermore, performance metrics such as response time and flow rate are vital indicators of a bleed valve's efficiency. Industry standards, such as those set by the American National Standards Institute (ANSI), recommend that buyers check the specifications of response times; valves should ideally react within milliseconds for optimal operations. Additionally, ensuring that the valve meets ISO 9001 certification standards can provide reassurance regarding its manufacturing quality and reliability. As the global market for industrial valves is projected to reach USD 90 billion by 2027, the emphasis on evaluating bleed valves robustly is more crucial than ever for buyers to ensure they invest in quality products that enhance process reliability and efficiency.

Regulatory Standards and Compliance for Global Buyers of Bleed Valves

When considering the purchase of bleed valves, understanding the regulatory standards and compliance requirements is crucial for global buyers.

Bleed valves are essential components in various industries, including oil and gas, water treatment, and manufacturing. Each region has specific regulations governing their design, testing, and operation. For instance, the American Society of Mechanical Engineers (ASME) standards in the United States ensure that these components can withstand high pressures and temperatures, while the European Union's Pressure Equipment Directive (PED) emphasizes safety and performance.

Compliance with these regulatory standards not only guarantees the safety and reliability of bleed valves but also facilitates smoother trade across borders. Buyers need to conduct due diligence on the manufacturers to ensure that they adhere to local and international standards. Certification from recognized bodies, such as the Underwriters Laboratories (UL) or the International Organization for Standardization (ISO), serves as a testament to a manufacturer's commitment to quality. By prioritizing regulatory compliance, global buyers can mitigate risks and ensure that their operations run smoothly and safely.