The Ultimate Guide to Sourcing Premium Econtrol Valves for Global Buyers

In the dynamic landscape of industrial automation, the demand for Econtrol Valves has surged significantly, reflecting the industry's need for precision and reliability in fluid control systems. According to a recent market analysis report by Global Industry Analysts, the global market for control valves is projected to reach $20.6 billion by 2026, driven by the rapid adoption of automation technologies and a focus on energy efficiency. This growth is indicative of the increasing importance of sourcing premium Econtrol Valves, which play a critical role in optimizing processes across various sectors, including oil and gas, water treatment, and chemical manufacturing. As global buyers navigate the complexities of sourcing these essential components, understanding the nuances of quality, performance, and supplier reliability becomes paramount. This ultimate guide aims to equip international buyers with the knowledge necessary to make informed decisions while sourcing top-notch Econtrol Valves that meet their unique operational needs.

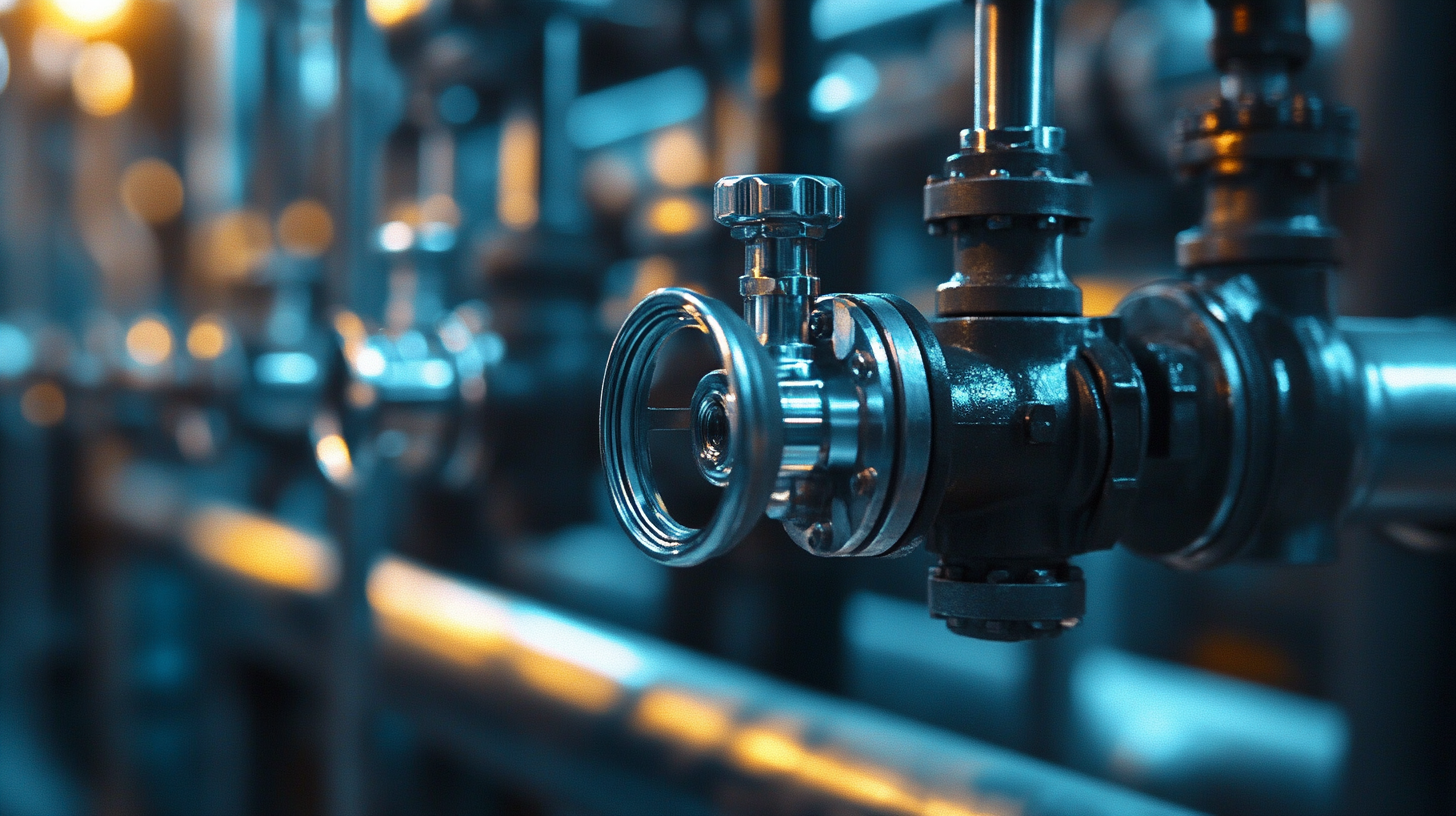

Understanding the Importance of Econtrol Valves in Global Industries

Econtrol valves play a crucial role in several global industries, serving as key components for regulating flow and pressure in various systems. According to a report by Research and Markets, the global valve market is projected to reach USD 93 billion by 2025, with econtrol valves becoming increasingly significant due to their efficiency and precision in automated processes. These valves not only enhance operational reliability but also contribute to energy savings, which is critical in sectors such as oil and gas, water management, and manufacturing.

The importance of econtrol valves is underscored in the petrochemical industry, where their failure can lead to substantial operational disruptions and financial losses. A study by Frost & Sullivan highlights that nearly 30% of maintenance costs in petrochemical facilities are a result of valve-related issues. As industries face increasing demands for sustainability and efficiency, investing in high-quality econtrol valves is becoming more essential than ever. With the anticipated growth of smart manufacturing and IoT applications, the demand for sophisticated econtrol valves that offer enhanced monitoring and control capabilities will only continue to rise.

The Ultimate Guide to Sourcing Premium Econtrol Valves for Global Buyers

| Dimension |

Material |

Application |

Pressure Rating |

Temperature Range |

Certification |

| 1" to 12" |

Stainless Steel |

Oil & Gas |

150 to 2500 PSI |

-20°F to 400°F |

API, ISO 9001 |

| 3" to 8" |

Carbon Steel |

Water Treatment |

150 to 600 PSI |

0°F to 300°F |

CE, ASME |

| 2" to 10" |

Bronze |

Chemical Processing |

150 to 1000 PSI |

-40°F to 350°F |

ISO 14001 |

| 1.5" to 6" |

PVC |

Pharmaceuticals |

100 to 400 PSI |

-20°F to 140°F |

FDA, NSF |

Key Features to Look for When Sourcing Econtrol Valves

When sourcing premium Econtrol valves, buyers should prioritize specific key features that ensure optimal performance and longevity. Firstly, material quality plays a critical role in the valve's durability and resistance to corrosion. Opt for valves constructed from high-grade metals or specialized alloys that can withstand various environmental conditions without compromising functionality. Additionally, consider the valve’s pressure ratings and temperature capabilities to ensure they meet the requirements of your application.

Another essential feature to evaluate is the valve's control precision. High-quality Econtrol valves should offer exceptional responsiveness and adjustment capabilities to provide accurate flow control. Look for valves that utilize advanced actuator technology, as these systems tend to enhance performance through improved speed and stability. Furthermore, ease of maintenance is crucial; selecting valves with accessible components will facilitate timely inspections and repairs, minimizing downtime in your operations. By focusing on these key features, global buyers can make informed decisions and secure the best Econtrol valves for their needs.

Top Suppliers and Manufacturers for Premium Econtrol Valves Worldwide

When sourcing premium econtrol valves, global buyers are faced with a myriad of choices. Identifying top suppliers and manufacturers is essential for ensuring the quality and reliability of these critical components. Notable players in the industry are known for their cutting-edge technology and innovative designs. Companies like OMEGA Engineering, Parker Hannifin, and Flowserve have established themselves as leaders, offering a range of econtrol valves that cater to various industrial applications. Their commitment to excellence and customer satisfaction makes them go-to suppliers for businesses aiming to optimize their operations.

In addition to established manufacturers, emerging suppliers are also making their mark by offering competitive pricing and customized solutions. Companies based in Asia, such as the Chinese manufacturer KSB and the Indian supplier KBL, are increasingly gaining recognition for their quality products at attractive price points. These manufacturers are leveraging modern manufacturing techniques and sustainable practices to produce efficient and durable econtrol valves. Buyers looking to source these components globally should consider both established and emerging players, ensuring they select the best fit for their specific operational needs and budget constraints.

Navigating Quality Standards and Certifications for Econtrol Valves

When sourcing premium Econtrol valves, navigating the maze of quality standards and certifications can significantly impact your purchasing decisions. Understanding the various international quality standards, such as ISO 9001 and API 6D, is essential for ensuring that the valves you source meet not only performance expectations but also legal and safety requirements in your specific industry. These standards provide a framework for consistent manufacturing practices and quality assurance, minimizing risks associated with product failure.

Moreover, certifications such as CE and UL indicate that a product complies with specific health, safety, and environmental protection standards, offering additional peace of mind. For global buyers, verifying these certifications allows for a more informed procurement process, ensuring that the valves can withstand rigorous testing and operate efficiently in diverse environments. As you delve deeper into the sourcing process, prioritizing suppliers who adhere to these quality frameworks will not only enhance the reliability of your projects but also build a reputation for excellence in your industry.

Cost-Effective Strategies for Sourcing Econtrol Valves Globally

When it comes to sourcing premium Econtrol valves on a global scale, understanding cost-effective strategies is essential for any buyer. One of the primary considerations should be the evaluation of suppliers based on their ability to deliver quality products at competitive prices. This involves conducting thorough market research to identify manufacturers that specialize in Econtrol valves and have a solid reputation for reliability and quality. Engaging in direct communication with suppliers can also lead to better pricing options and insights into bulk order discounts or special promotions that may not be advertised.

Another effective strategy is to leverage technology to streamline the sourcing process. Utilizing online platforms that connect buyers with manufacturers can significantly reduce overhead costs and time spent on logistics. Virtual trade shows and industry webinars also provide valuable opportunities to discover new suppliers and gain insights into the latest trends in Econtrol valve manufacturing. By incorporating these modern tools into the sourcing strategy, buyers can not only save costs but also ensure they are choosing the best possible products for their specific needs in the global market.

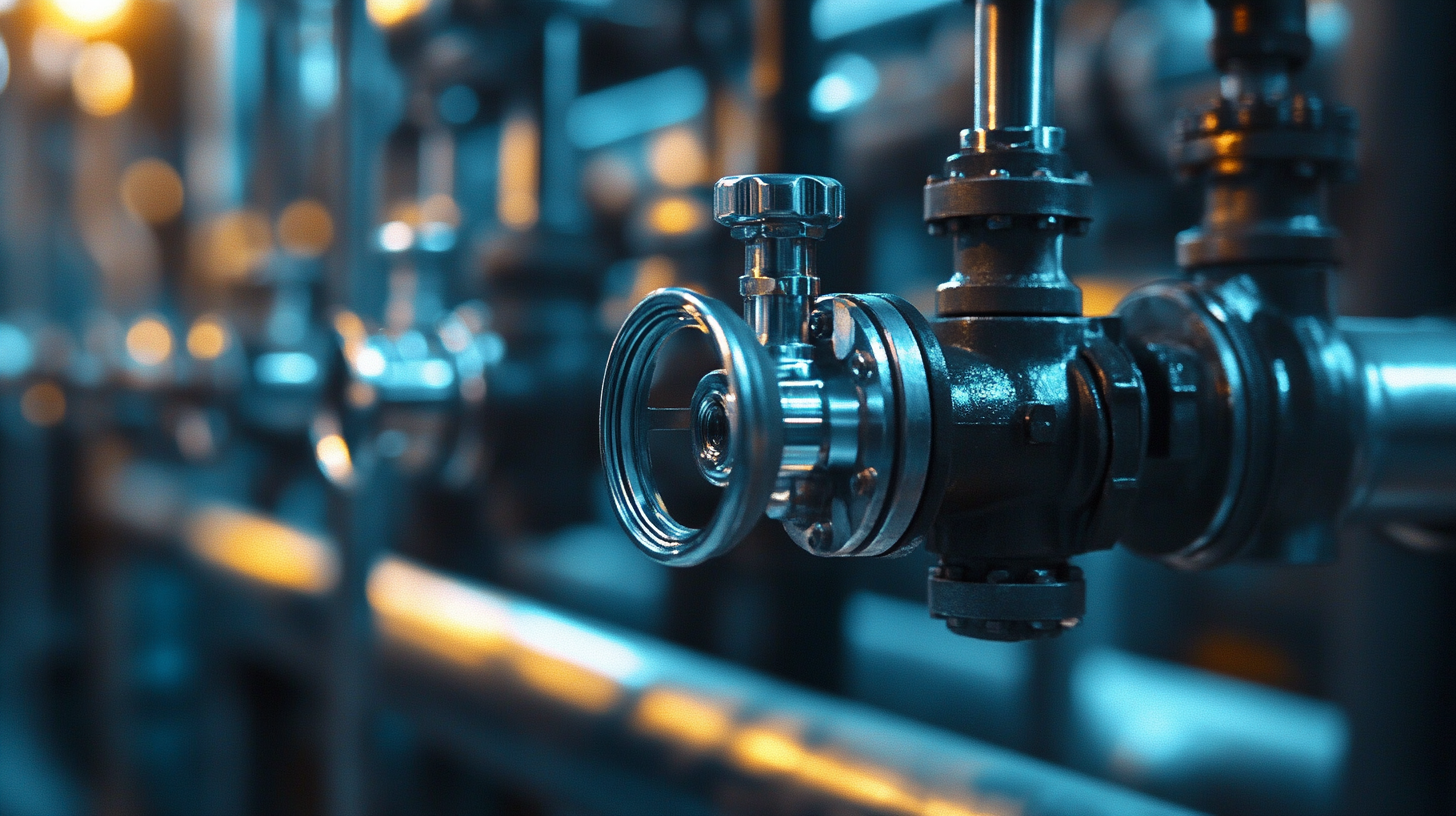

The Ultimate Guide to Sourcing Premium Econtrol Valves

This chart illustrates the average cost of sourcing econtrol valves from different regions around the world, comparing them based on their quality ratings. The data is collected from various suppliers to provide global buyers with insight into cost-effective strategies for sourcing these crucial components.