The Ultimate Checklist for Choosing the Best Diaphragm Valves for Your Needs

In the fluid control industry, diaphragm valves play a critical role in various applications, including pharmaceutical manufacturing, water treatment, and chemical processing. According to a report by Market Research Future, the global diaphragm valve market is expected to reach USD 2.32 billion by 2025, growing at a CAGR of 4.5% during the forecast period. This growth underscores the importance of selecting the right diaphragm valves to ensure optimal performance and reliability. However, with numerous options available, selecting the best diaphragm valves for your specific needs can be a daunting task. It is essential to consider various factors such as material compatibility, size, and actuation methods. This ultimate checklist aims to guide you through the critical aspects to evaluate when selecting diaphragm valves, ensuring that you make an informed decision that meets both operational requirements and industry standards.

Understanding the Basics of Diaphragm Valves: Types and Functions

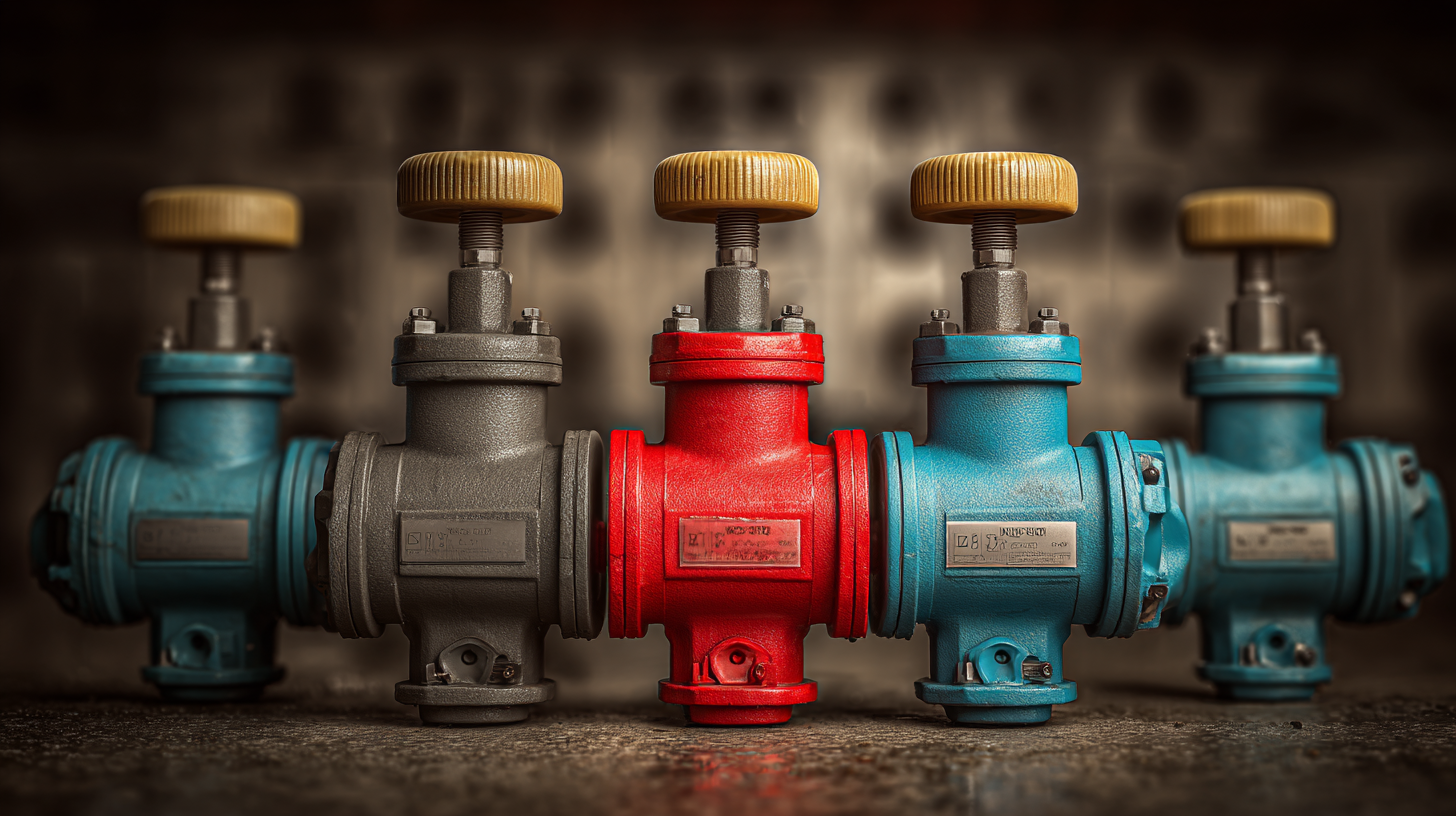

Diaphragm valves are essential components in various applications, renowned for their efficient control of fluid flow. Understanding the types and functions of diaphragm valves can significantly enhance decision-making when it comes to choosing the right one for your needs. Generally, diaphragm valves can be classified into three main types: weir type, straight through type, and angle type. Each type serves a distinct purpose, from maximizing flow in straight-through designs to better handling viscous fluids in weir configurations.

When selecting a diaphragm valve, it's important to consider the material compatibility with the fluid being handled. For instance, applications involving corrosive substances may require valves made from materials resistant to chemical reactions. Additionally, evaluating the operating pressure and temperature is crucial to ensure that the valve performs reliably under specific conditions.

Tips: Always consult manufacturers for detailed specifications to ensure the diaphragm valve you choose meets the operational standards of your system. Moreover, consider the maintenance and replacement aspects; choosing a valve with readily available parts can save time and cost in the long run.

Key Factors to Consider When Selecting Diaphragm Valves for Your Project

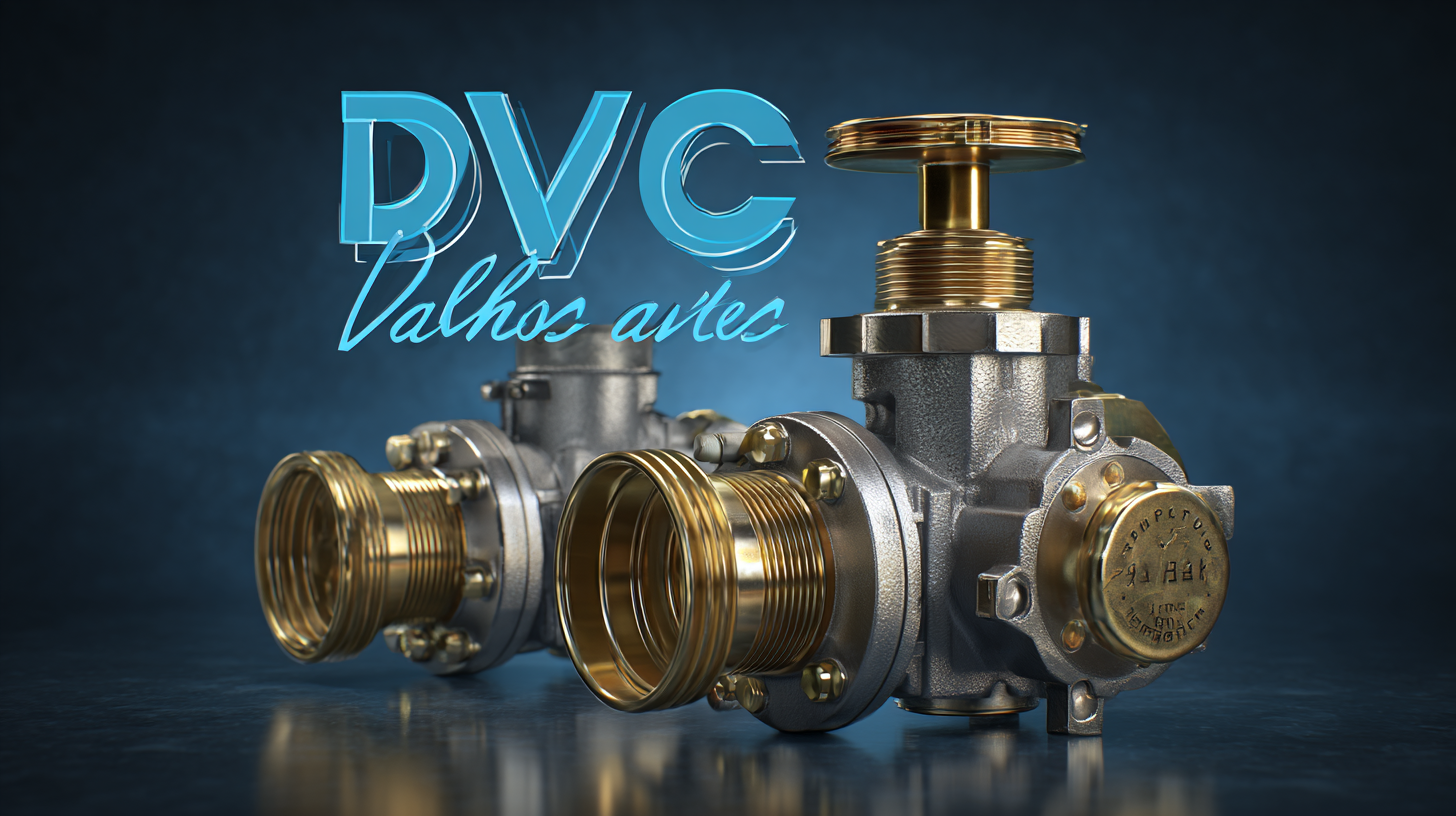

When selecting diaphragm valves for your project, it's essential to consider several key factors to ensure optimal performance and longevity. One of the most critical aspects is the valve material. According to a report by the Global Diaphragm Valve Market, the right material can significantly influence the valve's resistance to corrosion and its overall durability, especially in demanding applications such as chemical processing. Materials like PTFE and PVC are often recommended for aggressive media, while stainless steel offers strength and reliability in various environments.

Another vital factor is the valve design and configuration. The actuation method, whether manual or automated, can impact the efficiency of your system. A study published by Valve Magazine emphasizes that improper valve selection can lead to operational failures, costing companies up to 20% of their annual maintenance budget. Always opt for a design that matches your specific flow rate and pressure conditions to avoid unnecessary complications.

Tips:

- Always verify the compatibility of the diaphragm material with the media it will contact to prevent chemical degradation.

- Consider the environment where the valve will be installed; extreme temperatures or pressures may require specialized designs.

- Regularly consult industry standards to ensure your selected diaphragm valves meet all compliance regulations for your specific application.

Comparing Materials and Designs: Which Diaphragm Valve is Right for You?

When selecting the right diaphragm valve, it’s essential to consider both the materials and designs that cater to your specific applications. The material of the diaphragm itself plays a crucial role in the valve's performance, with options ranging from rubber and PTFE to more exotic materials like EPDM or FKM. Each material has distinct properties: for instance, PTFE offers excellent chemical resistance, while EPDM provides superior elasticity and weather resistance. Therefore, understanding the conditions your valve will face—such as temperature, pressure, and the type of media being handled—is fundamental to making an informed choice.

Another important aspect to consider is the design of the diaphragm valve. Traditional designs, such as weir-type and straight-through configurations, each offer unique advantages depending on the flow requirements and space constraints of your system. Weir-type valves are known for their compact design and ability to handle slurries or viscous fluids, whereas straight-through designs minimize pressure drops and facilitate smoother operations for clean, low-viscosity liquids. By carefully comparing these elements, you can ensure that your diaphragm valve selection aligns perfectly with the operational demands of your application, leading to enhanced efficiency and longevity in your systems.

Quality Assurance and Testing Standards for Diaphragm Valves in Manufacturing

When selecting diaphragm valves for your applications, understanding the quality assurance and testing standards in manufacturing is crucial. Manufacturers typically adhere to strict guidelines set forth by organizations such as the International Organization for Standardization (ISO) and the American Society for Testing and Materials (ASTM). These standards ensure that diaphragm valves not only meet performance requirements but also exceed safety and durability expectations. By prioritizing suppliers who embrace these rigorous testing protocols, you can significantly reduce the risk of valve failure in critical processes.

Moreover, various testing methods are employed to evaluate the integrity and functionality of diaphragm valves. These include pressure testing, leak testing, and cycling tests that simulate real-world operation under different conditions. The effectiveness of these tests translates directly into the reliability of the valves you choose. It is essential to inquire about these testing practices when assessing potential suppliers, as transparency regarding quality assurance measures is a strong indicator of their commitment to producing top-notch products. This vigilance in your selection process can lead to long-term operational success and ensure compliance with industry regulations.

The Ultimate Checklist for Choosing the Best Diaphragm Valves for Your Needs

| Criteria |

Description |

Standard Compliance |

| Material Quality |

Ensure material is durable and suitable for the process media. |

ASTM, ISO 9001 |

| Pressure Ratings |

Check the valve's ability to handle process pressure without failure. |

ANSI/ISA, API |

| Testing Standards |

Verify that the valves meet specific testing guidelines. |

ISO 2878, ASME B16.34 |

| Certification |

Look for certifications indicating compliance with industry standards. |

CE, UL, CSA |

| Size & Compatibility |

Ensure valve fits the existing pipeline dimensions and connections. |

DIN, ISO 16 |

The Future of Diaphragm Valves: Innovations and Trends in the Industry

In recent years, diaphragm valves have undergone significant innovations, reflecting the changing demands of various industries. The future of diaphragm valves lies in their enhanced efficiency, durability, and adaptability to modern systems. Manufacturers are increasingly focusing on materials that improve corrosion resistance and extend the life of the valves, ensuring that they meet the high standards of today's applications. Technology integration, such as smart sensors and automation, also plays a crucial role in optimizing valve performance and reliability.

When selecting diaphragm valves, it's essential to stay updated on the latest trends. One tip is to consider valves with advanced sealing technologies. These innovations not only reduce leakage but also offer better control over flow rates, which is crucial for maintaining system integrity. Additionally, look for options that provide easy maintenance features, as this can significantly reduce downtime and operational costs.

Another important aspect is compatibility with various fluids and pressure ranges. It's advisable to assess the specific conditions of your application and opt for diaphragm valves designed to handle those parameters. By prioritizing future-ready solutions, you can enhance the efficiency and effectiveness of your operations while staying ahead in a competitive market.