Top Strategies for Selecting the Best Control Valves for Your Industrial Needs

The demand for control valves in industrial applications is set to soar, with projections indicating the global control valves market will reach approximately $12 billion by 2025, driven by advancements in automation and the increasing need for efficient process control. As industries continue to prioritize operational efficiency and sustainability, the selection of the right control valves becomes a critical factor in optimizing performance and reducing operational costs. Factors such as material compatibility, valve size, and the specific requirements of each application play a significant role in this decision-making process. According to a recent market analysis, the demand for intelligent control valves, equipped with advanced monitoring and diagnostic capabilities, is expected to grow substantially, reflecting a shift towards smart manufacturing practices. This blog will explore the top strategies for selecting the best control valves that meet the evolving needs of various industrial sectors.

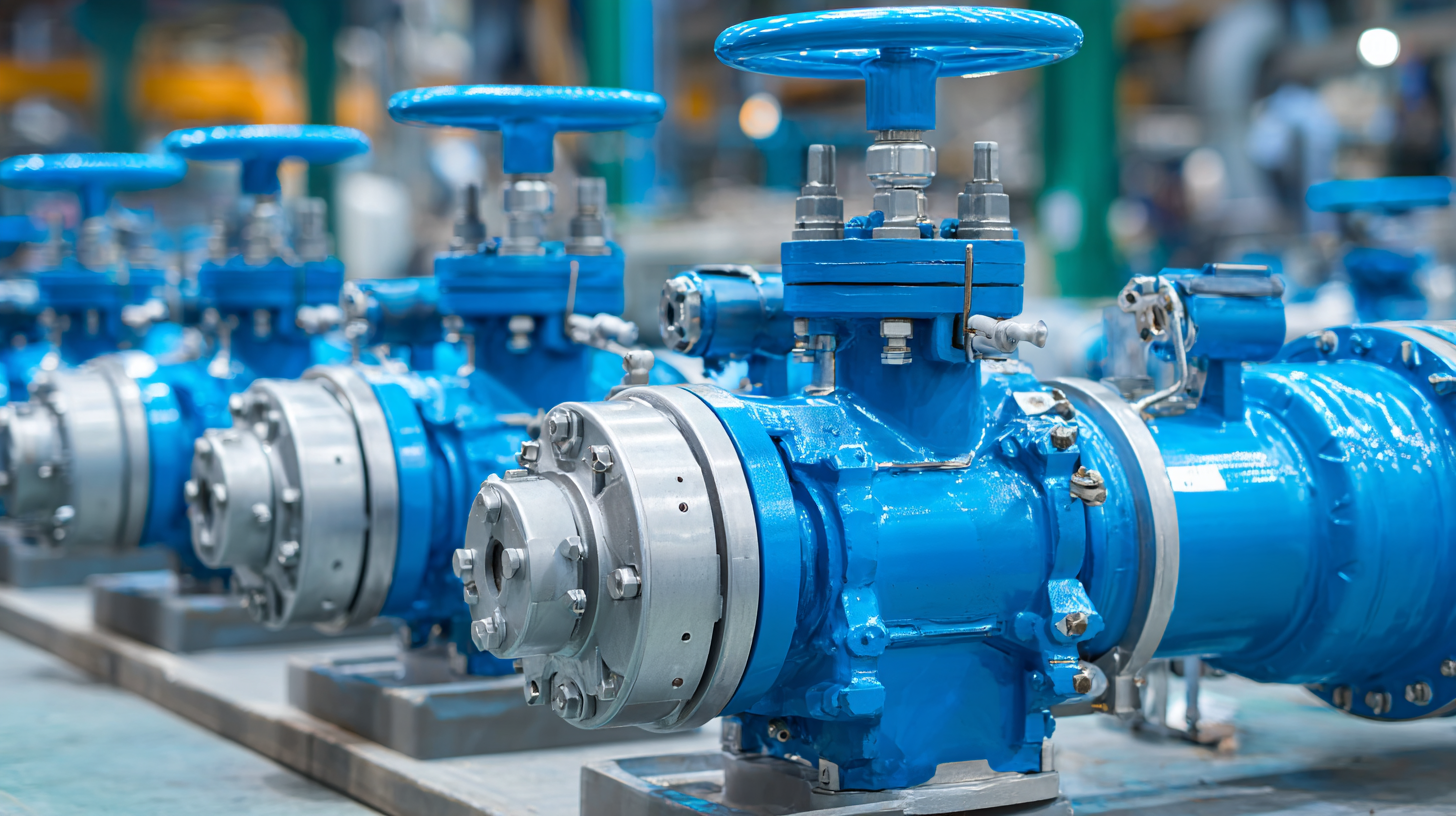

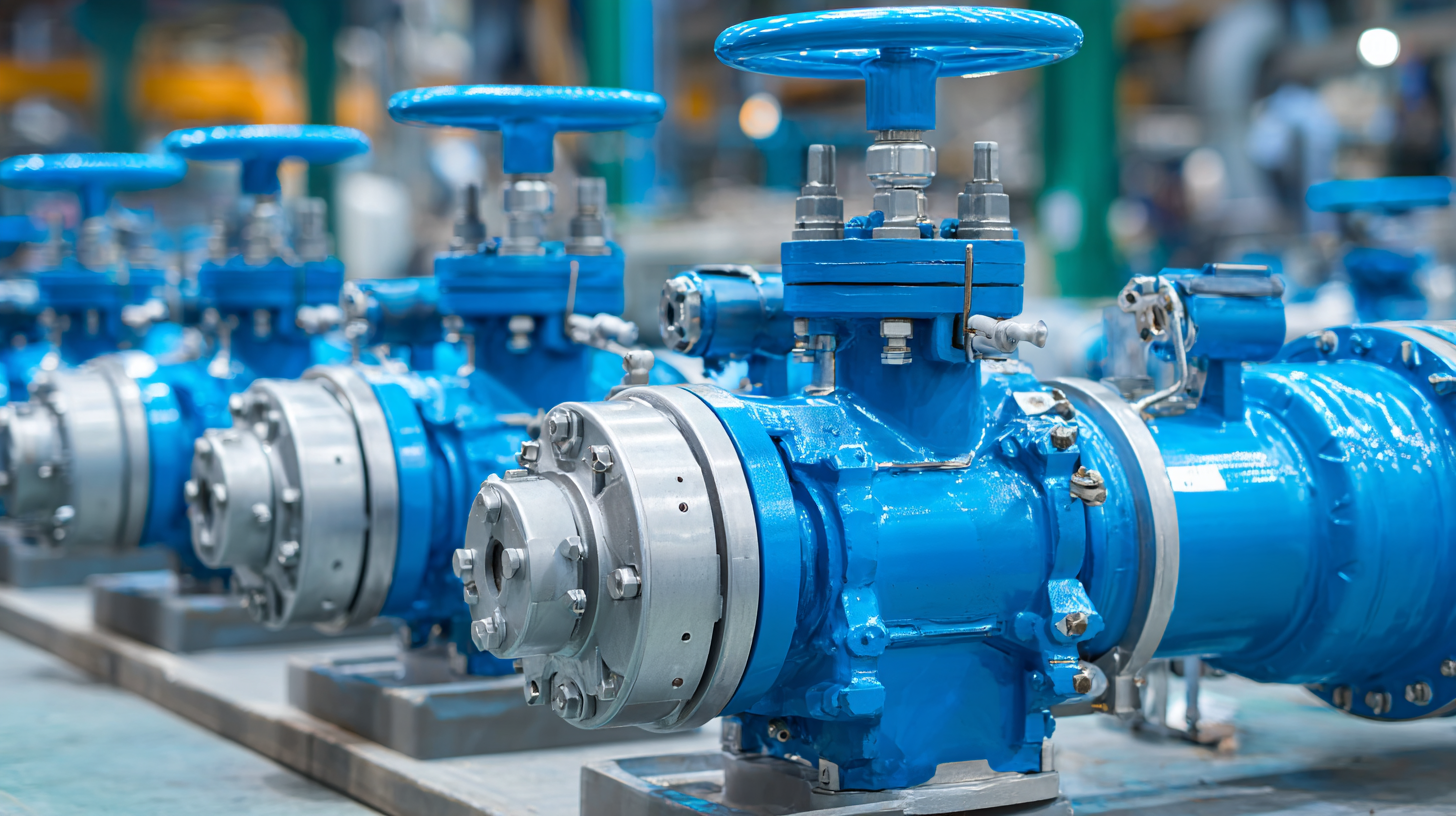

Essential Factors to Consider When Choosing Control Valves for Industrial Applications

When selecting control valves for industrial applications, several essential factors play a pivotal role in ensuring optimal performance and efficiency. Firstly, flow characteristics and valve sizes are crucial. According to a report from the International Society of Automation (ISA), 70% of valve performance issues stem from improper sizing. It is imperative to analyze the specific flow requirements and pressure drops in your system before choosing a control valve that fits these parameters, ensuring that the valve can effectively manage the flow rates necessary for your processes.

Another significant consideration is the material of construction. The choice of materials directly affects the valve's ability to withstand corrosive fluids and high temperatures. A study by the Flow Control Magazine indicates that over 50% of industrial system failures are related to material degradation. It is essential to select materials that are compatible with the media being controlled, factoring in temperature, pressure, and fluid type to prevent premature wear and costly downtimes. Understanding these key factors can lead to more reliable and efficient industrial operations.

The Impact of 2025 Industry Trends on Control Valve Selection

As we approach 2025, the industrial landscape is undergoing significant transformation, impacting control valve selection across various sectors. With the rise of smart manufacturing and the Internet of Things (IoT), control valves are no longer just mechanical components; they have become integral to automated systems that enhance operational efficiency and data analysis. Selecting the right control valves entails considering their compatibility with advanced control systems, ensuring they are equipped with smart features like remote monitoring and diagnostics.

Moreover, sustainability is becoming a pivotal aspect in industrial operations. The increased emphasis on reducing carbon footprints and optimizing energy consumption means that control valves must be chosen not only for their performance but also for their energy efficiency. As industries adapt to regulatory changes and environmental standards, choosing valves that support these goals is crucial. Therefore, staying abreast of these trends will empower industrial leaders to make informed decisions, ensuring that their control valve selections align with both current operational needs and future industry shifts.

Top Strategies for Selecting the Best Control Valves for Your Industrial Needs - The Impact of 2025 Industry Trends on Control Valve Selection

| Selection Criteria |

Description |

Impact of 2025 Trends |

| Material Compatibility |

Ensuring the valve material can withstand the process media. |

Increased focus on sustainable materials. |

| Pressure Rating |

Selecting valves based on the maximum pressure conditions. |

Higher performance requirements in extreme conditions. |

| Size and Flow Rate |

Matching valve size to the pipeline and required flow rates. |

Adoption of more flexible, modular designs. |

| Actuation Type |

Choosing between manual, pneumatic, or electric actuators. |

Rise in automation and smart technology integration. |

| Maintenance Requirements |

Understanding the upkeep and care needed for the valve. |

Increased emphasis on reliability and reduced downtime. |

| Cost Considerations |

Evaluating the total cost of ownership over the valve's life. |

Focus on cost-effective solutions coupled with efficiency gains. |

Innovative Solutions for Common Challenges in Control Valve Implementation

Selecting the best control valves for industrial needs involves navigating common challenges, particularly in the context of innovative solutions. As industries increasingly adopt smart technologies, such as those found in the Internet of Things (IoT), the demand for control valves that can seamlessly integrate with these systems is growing. Innovations in control valve design can help enhance process efficiency and sustainability. For instance, newer materials and coatings similar to those being researched for mechanical heart valves could improve durability and performance in harsh industrial environments.

**Tip:** When evaluating control valves, consider how they can be integrated with IoT systems to enable real-time data monitoring and optimization. This integration can lead to significant improvements in operational efficiency.

Additionally, adopting advanced technologies, such as machine learning, can further refine control valve selection processes. By analyzing performance data, companies can make better-informed decisions that align with their energy efficiency goals. The focus should be on valves that offer adaptability and enhanced functionality in response to changing demands.

**Tip:** Implement a proactive maintenance strategy powered by predictive analytics to ensure that selected valves continue to meet operational specifications, ultimately reducing downtime and maintenance costs.

Control Valve Selection Criteria

Comparative Analysis of Different Types of Control Valves for Optimal Performance

When it comes to selecting control valves for industrial applications, understanding the various types available and their specific functionalities is crucial for achieving optimal performance. Control valves can be classified into several categories, including globe, ball, butterfly, and safety valves, each serving different operational needs. For instance, globe valves are known for their ability to regulate flow with precision, making them ideal for applications requiring throttling capabilities. In contrast, ball valves provide quick shut-off and are frequently used in systems requiring rapid valve actuation.

Comparative analysis of these valve types reveals that choosing the right control valve depends on the specific requirements of the application, such as pressure, temperature, and flow rate. Balloon valves, with their simple design, offer low-pressure drops and high flow capacity, but may not perform as effectively in throttling scenarios. Conversely, butterfly valves are excellent for applications with large flow capacities and can pivot to modulate flow efficiently. Assessing the advantages and drawbacks of each type helps engineers make informed decisions, ensuring the selected control valve aligns with the operational demands of their facility while enhancing overall process efficiency.

Future-Proofing Your Control Valve Choices: Ensuring Longevity and Efficiency

When selecting control valves for industrial applications, it’s crucial to focus on longevity and efficiency to ensure future-proofing. Recent industry reports indicate that the global control valve market is projected to reach USD 8.6 billion by 2027, reflecting an annual growth rate of 6.7%. This growth can be attributed to increasing automation in industries and the rising demand for energy-efficient solutions. Choosing high-quality control valves can significantly impact operational efficiency and maintenance costs over time.

Investing in valves with advanced materials and cutting-edge technology is essential. For instance, valves incorporating smart technologies can enhance performance by providing real-time data on flow and pressure conditions, allowing for proactive maintenance and avoiding potential failures. Industry professionals suggest evaluating metrics such as flow coefficient (Cv), pressure drop, and operating temperature range, ensuring that your selections not only meet current demands but are also adaptable to future requirements as industry standards evolve. By prioritizing these factors in your procurement process, you can secure control valves that contribute to sustained efficiency and operational excellence in your facility.