What is the Importance of Diaphragm Valves in Modern Industrial Applications

Diaphragm Valves play a crucial role in modern industrial applications, serving as essential components in fluid control systems across various sectors, including pharmaceuticals, food and beverage, and chemical processing. According to a recent market research report by Allied Market Research, the global diaphragm valve market is projected to reach $5.3 billion by 2026, growing at a CAGR of 4.2% from 2019.

This growth is driven by the rising demand for safe and reliable fluid handling solutions, particularly in industries that require high purity and contamination-free environments. Moreover, diaphragm valves are known for their excellent sealing capabilities and ease of maintenance, making them ideal for applications involving corrosive and aggressive fluids. As industries continue to prioritize efficiency and sustainability, the importance of diaphragm valves in ensuring optimal performance and safety in fluid management cannot be overstated.

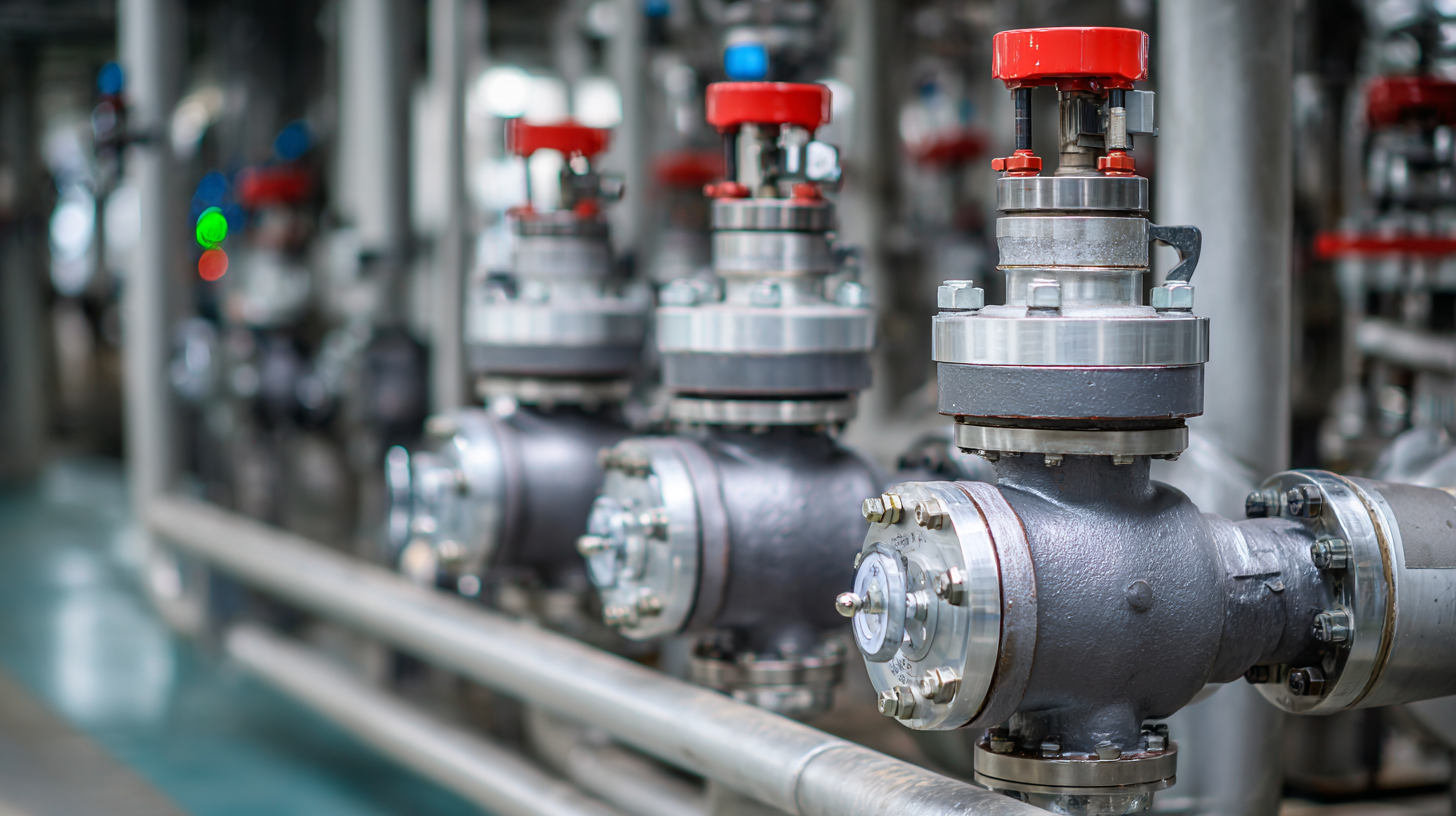

The Role of Diaphragm Valves in Controlling Fluid Flow in Industrial Processes

Diaphragm valves play a crucial role in the regulation of fluid flow within various industrial processes. Their unique design allows for precise control over the flow of liquids and gases, making them invaluable in applications such as chemical processing, water treatment, and pharmaceuticals. The diaphragm, typically made from elastomeric materials, serves as a flexible barrier that can open and close the flow path efficiently, ensuring minimal leakage and enhancing the reliability of the system.

One of the key advantages of diaphragm valves is their ability to handle a wide range of pressures and temperatures, which is essential in demanding industrial environments. They provide excellent throttling capabilities, allowing operators to adjust flow rates easily. Additionally, the lock-tight design minimizes contamination risks, making diaphragm valves particularly well-suited for sanitary applications. This reliability and versatility underscore their significance in maintaining safety and operational efficiency in modern industrial settings. Ultimately, diaphragm valves are integral to optimizing fluid control and ensuring smooth operations across a variety of sectors.

Key Advantages of Diaphragm Valves in Corrosive and Hazardous Environments

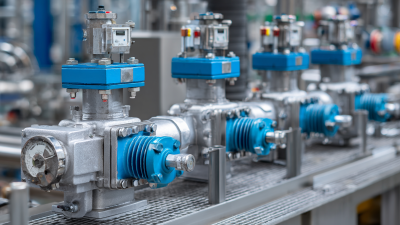

Diaphragm valves play a critical role in modern industrial applications, especially in environments that handle corrosive and hazardous substances. Their unique design, which uses a flexible diaphragm to control flow, minimizes the risk of leakage and contamination, making them ideal for industries such as chemicals, pharmaceuticals, and food processing. In these sectors, any failure in valve integrity can lead to severe safety hazards and costly downtime, underscoring the importance of reliable valve technology.

Recent advancements in diaphragm valve technology, including the introduction of enhanced manual process valve offerings, have further improved their functionality and reliability. The updated products, including various configurations like basic and full function diaphragm valves, enable industries to tailor solutions according to specific operational needs. This level of customization is particularly advantageous in corrosive environments, where material compatibility is crucial. Additionally, new electrically-operated diaphragm pumping solutions have emerged, offering energy-efficient options that enhance operational effectiveness while maintaining safety in handling hazardous fluids.

Market Trends: Growth and Demand for Diaphragm Valves in Various Industries

The diaphragm valve market is witnessing significant growth, driven by its essential applications across various industries. As per recent market research, the global semiconductor diaphragm valve market is expected to surpass $2.1 billion by 2034, highlighting a growing trend in precision industries. The increasing demand for efficient flow control systems in sectors such as pharmaceuticals, food processing, and semiconductor manufacturing is a key factor fueling this growth. The ability of diaphragm valves to handle corrosive and viscous fluids makes them a preferred choice for many industrial applications.

Moreover, the global air compressor rental market is projected to reach USD 8,221.1 million by 2033, growing at a CAGR of 6.8%. The rise in rental services is attributed to the need for cost-effective solutions in industries where the demand for compressed air fluctuates. This trend reflects a broader shift toward adaptable and flexible operational strategies in industrial applications, further emphasizing the significance of reliable valve technologies, including diaphragm valves, which offer superior pressure control and safety.

**Tips:** When selecting diaphragm valves, consider the specific fluid characteristics and operational pressures to ensure optimal performance. Additionally, staying updated on market trends can help organizations make informed decisions regarding their equipment investments, especially in rapidly evolving sectors like semiconductor manufacturing and renewable energy.

Importance of Diaphragm Valves in Modern Industrial Applications

The chart above illustrates the market demand for diaphragm valves across various industries in million USD. The highest demand is observed in the Water & Wastewater sector, followed by Pharmaceutical and Food & Beverage industries. These trends reflect the growing importance of diaphragm valves in ensuring safety and operational efficiency in modern industrial applications.

Performance Metrics: Efficiency and Reliability of Diaphragm Valves Compared to Traditional Valves

Diaphragm valves have gained prominence in modern industrial applications due to their superior performance metrics, particularly in terms of efficiency and reliability when compared to traditional valve types. The construction of diaphragm valves, which features a flexible membrane that seals the flow path, allows for precise control of fluid flow. This design not only minimizes leakage but also prevents contamination, making diaphragm valves especially suitable for applications in industries such as pharmaceuticals, food processing, and wastewater treatment.

Diaphragm valves have gained prominence in modern industrial applications due to their superior performance metrics, particularly in terms of efficiency and reliability when compared to traditional valve types. The construction of diaphragm valves, which features a flexible membrane that seals the flow path, allows for precise control of fluid flow. This design not only minimizes leakage but also prevents contamination, making diaphragm valves especially suitable for applications in industries such as pharmaceuticals, food processing, and wastewater treatment.

In terms of reliability, diaphragm valves outperform traditional valves by offering a longer service life and lower maintenance needs. Their simple design reduces the likelihood of mechanical failure and allows them to operate effectively in challenging conditions, including high-pressure environments and corrosive substances. Moreover, diaphragm valves provide consistent performance over time, which is crucial for industrial processes that require exact flow regulation. This combination of efficiency and reliability highlights their essential role in enhancing operational effectiveness across various sectors.

Future Innovations: Technological Advances Shaping Diaphragm Valve Design and Functionality

Diaphragm valves are becoming increasingly crucial in modern industrial applications, especially with the ongoing innovations shaping their design and functionality. One of the most significant trends is the integration of advanced materials and technologies to enhance their performance and reliability. The rising demand for precise flow control in critical applications, such as nuclear power generation, has highlighted the importance of these valves in maintaining safety and efficiency.

Recent developments in the field, particularly in atomic layer deposition (ALD) techniques, are paving the way for the creation of ultra-pure diaphragm valves that can effectively manage complex fluid dynamics. With the growing emphasis on energy sustainability, the nuclear power sector is experiencing a surge in demand for sophisticated valve solutions to regulate flow, temperature, pressure, and direction within pipelines. This evolution is not just limited to nuclear applications but extends across various high-tech industries requiring stringent process controls.

**Tips:** When selecting diaphragm valves for your operations, consider the application’s specific requirements for pressure, temperature, and fluid compatibility. Staying informed about the latest technological advancements can also provide competitive advantages in efficiency and safety. Moreover, investing in high-quality valves can significantly reduce maintenance costs and enhance system reliability.