The Future of Smart Automation: Transforming Industries with Best Automated Valves

The landscape of industrial automation is evolving at an unprecedented pace, with research indicating that the global market for automated valves is projected to reach $6.29 billion by 2026, growing at a CAGR of 6.2% from 2021 to 2026. This surge underscores the critical role automated valves play in enhancing operational efficiency, reducing human error, and ensuring safety across various sectors, including oil and gas, water treatment, and manufacturing. As industries increasingly embrace smart automation technologies, the integration of advanced automated valves is set to transform workflows, optimize performance, and support sustainability initiatives. With real-time data processing capabilities and improved control systems, automated valves not only streamline operations but also contribute significantly to resource conservation and environmental protection, making them a vital component of the future industrial ecosystem.

The Evolution of Smart Automation in Modern Industries

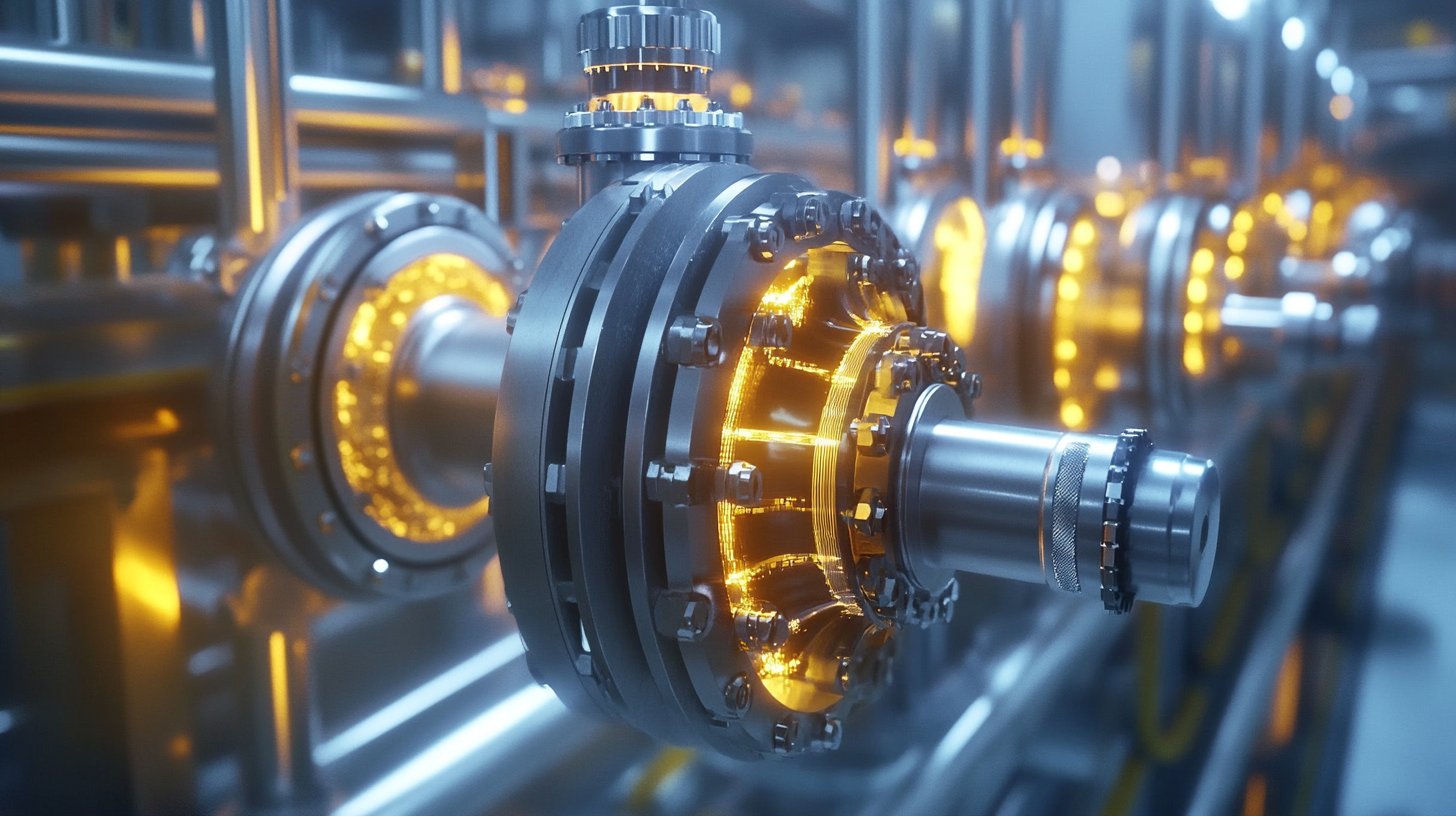

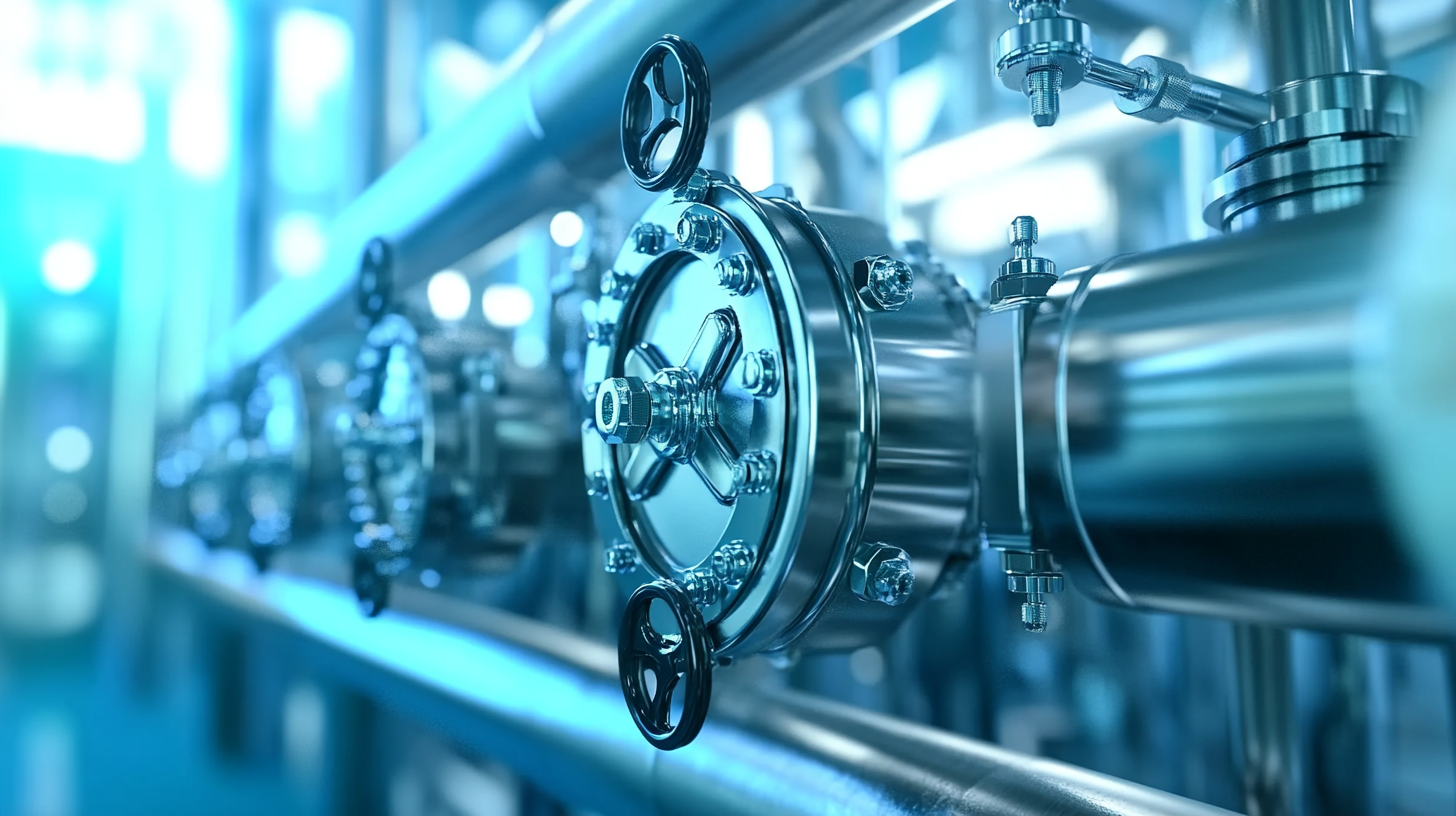

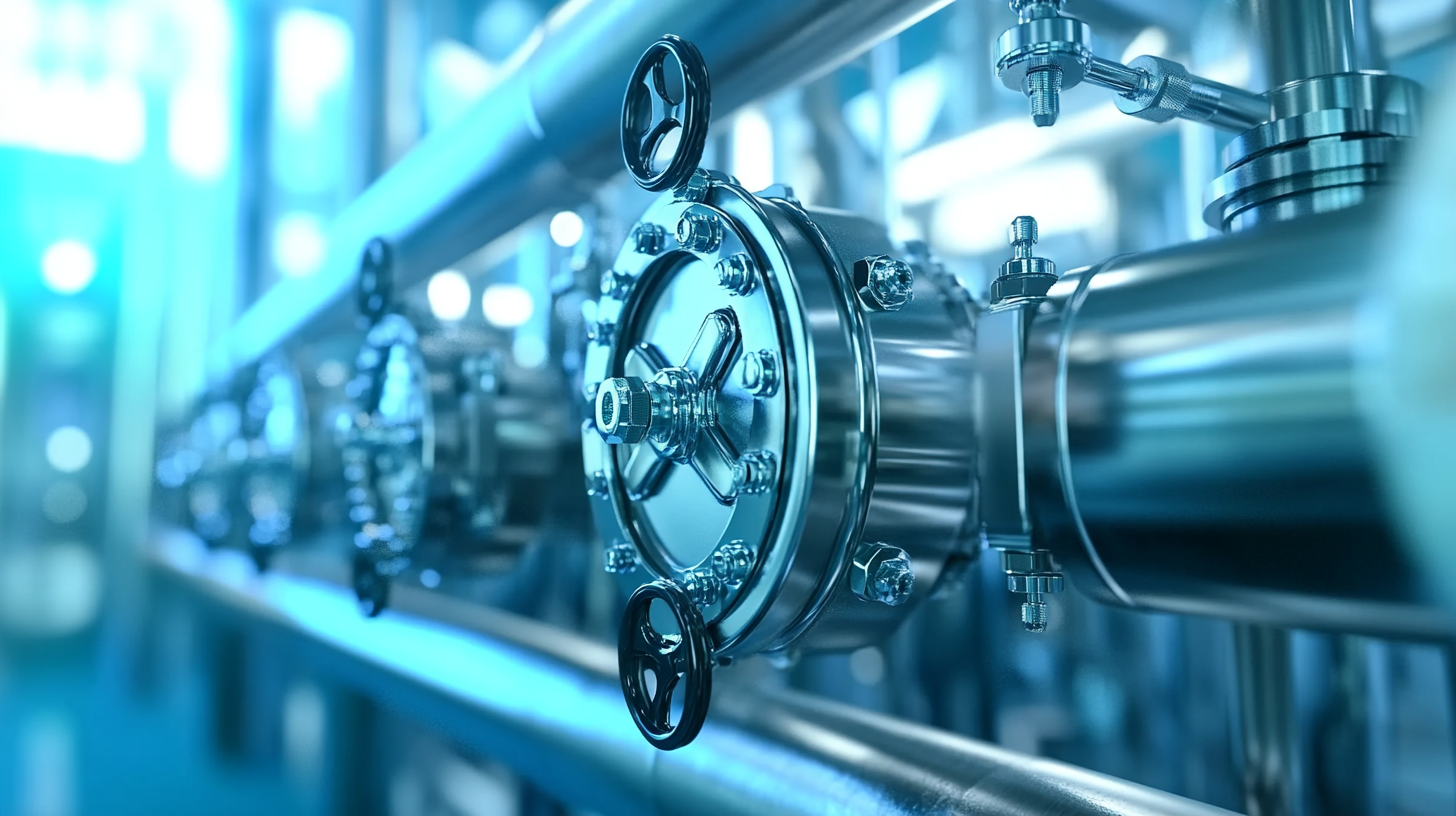

The evolution of smart automation has significantly transformed modern industries, paving the way for increased efficiency, reliability, and safety. As industries across the globe embrace advanced technologies, automated valves have emerged as crucial components in this transformation. With the integration of Internet of Things (IoT) capabilities and artificial intelligence, these valves not only perform their primary function of managing fluid flow but also offer real-time monitoring and predictive maintenance features. This shift from traditional to automated systems has enabled industries to optimize their operations, reduce downtime, and enhance productivity.

The evolution of smart automation has significantly transformed modern industries, paving the way for increased efficiency, reliability, and safety. As industries across the globe embrace advanced technologies, automated valves have emerged as crucial components in this transformation. With the integration of Internet of Things (IoT) capabilities and artificial intelligence, these valves not only perform their primary function of managing fluid flow but also offer real-time monitoring and predictive maintenance features. This shift from traditional to automated systems has enabled industries to optimize their operations, reduce downtime, and enhance productivity.

Moreover, the incorporation of smart valves into various sectors, such as oil and gas, water treatment, and manufacturing, exemplifies the versatility and necessity of smart automation. These valves are designed to adapt to complex environments, ensuring that process control becomes more accurate and responsive. As data analytics evolve, industries can harness valuable insights to make informed decisions, driving further innovation and competitiveness. The continuous advancements in smart automation technologies signify a promising future, empowering industries to navigate challenges more effectively while maintaining sustainability and operational excellence.

Key Advantages of Automated Valves in Industrial Applications

Automated valves are rapidly becoming essential components in modern industrial applications, revolutionizing efficiency and safety across various sectors. One of the key advantages of these advanced control systems is their ability to provide precise flow regulation. By automating the opening and closing of valves, industries can ensure accurate fluid management, which is crucial for maintaining optimal operating conditions. This precision not only reduces waste but also minimizes the risk of equipment damage, ultimately leading to cost savings and improved productivity.

Another significant benefit of automated valves is their capability for remote monitoring and control. Utilizing smart automation technologies, industries can track valve performance in real time, allowing for proactive maintenance and swift responses to potential issues. This level of oversight enhances operational reliability and supports safety protocols, as potential leaks or malfunctions can be identified and addressed before they escalate into more serious problems. As industries continue to integrate advanced automation solutions, the adoption of automated valves will undoubtedly play a pivotal role in driving innovation and operational excellence.

The Future of Smart Automation: Transforming Industries with Best Automated Valves

| Application Area |

Type of Automated Valve |

Key Advantages |

Efficiency Improvement (%) |

Common Industries |

| Water Treatment |

Ball Valve |

Reduced leakage, quick operation |

15-20 |

Municipal, Industrial |

| Oil & Gas |

Gate Valve |

Higher flow rate, reliability |

25-30 |

Petroleum, Offshore |

| Food Manufacturing |

Butterfly Valve |

Sanitary design, minimal hold-up volume |

10-15 |

Food & Beverage |

| Chemical Processing |

Globe Valve |

Excellent throttling control |

20-25 |

Chemicals, Pharmaceuticals |

China's Role in Global Manufacturing of Quality Automated Valves

China has emerged as a global leader in the manufacturing of quality automated valves, playing a pivotal role in transforming industries through smart automation. The rapid development of advanced manufacturing technologies in China has allowed companies to produce highly efficient and reliable automated valves that meet the growing demands of various sectors, including oil and gas, pharmaceuticals, and water management. With a focus on innovation and quality, Chinese manufacturers are setting the benchmark for the global market.

When integrating automated valves into your operations, consider the following tips. First, prioritize compatibility with existing systems to ensure seamless integration and minimal disruption. This can enhance efficiency and reduce operational costs. Secondly, invest in training for your staff to familiarize them with the features and maintenance of these advanced systems. Proper knowledge of automated valves can significantly extend their lifespan and optimize performance.

As the demand for smart automation continues to grow, the importance of sourcing quality automated valves from reputable manufacturers becomes increasingly vital. Establishing strong partnerships with Chinese manufacturers not only ensures access to cutting-edge technology but also promotes sustainable practices. Emphasizing innovation and quality will undoubtedly enhance productivity across industries, establishing a new era of smart automation.

The Future of Smart Automation: Transforming Industries with Best Automated Valves

Innovative Technologies Driving the Future of Smart Valves

The landscape of smart automation is rapidly evolving, driven by innovative technologies aimed at enhancing the efficiency and functionality of industries worldwide. Among these advancements, automated valves stand at the forefront, transforming how processes are managed in sectors such as manufacturing, energy, and water management. With the ability to integrate seamlessly into smart systems, these valves optimize operations and minimize human intervention, facilitating a more streamlined workflow.

One of the key elements in advancing smart valve technology is the incorporation of IoT connectivity. This enables real-time monitoring and control, allowing operators to make informed decisions based on live data. Investing in training for staff to understand these technologies is crucial. It can maximize the potential benefits of smart automation and ensure that the workforce is equipped with the necessary skills to handle new systems effectively.

As industries recognize the importance of mobility, innovations such as smart manufacturing and advanced powertrain systems are becoming essential. Organizations should consider exploring collaborative partnerships that foster innovation, ensuring they remain competitive. Regular assessments of the evolving trends in smart automation can also guide investment decisions, helping businesses stay ahead in a changing market.

Case Studies: Transformative Impacts of Automation on Industry Sectors

The advancement of smart automation is reshaping various industries, particularly through the integration of automated valves. A recent report by MarketsandMarkets indicates that the global automated valve market is projected to reach $9.9 billion by 2025, growing at a CAGR of 6.5% from 2020. This uptick signifies a widespread acceptance of automation technologies that optimize operational efficiency and reduce human error.

Case studies across different sectors highlight the transformative impact of this technology. In the oil and gas industry, automated valves have streamlined operations by remotely controlling the flow of critical resources, which has led to a 30% reduction in operational costs according to a report by McKinsey. Similarly, the water management sector has witnessed improvements in distribution efficiency and leak detection, with automated systems reporting a 20% decrease in water loss. These cases underscore how automated valves not only enhance productivity but also contribute significantly to sustainability efforts across industries.

The evolution of

The evolution of