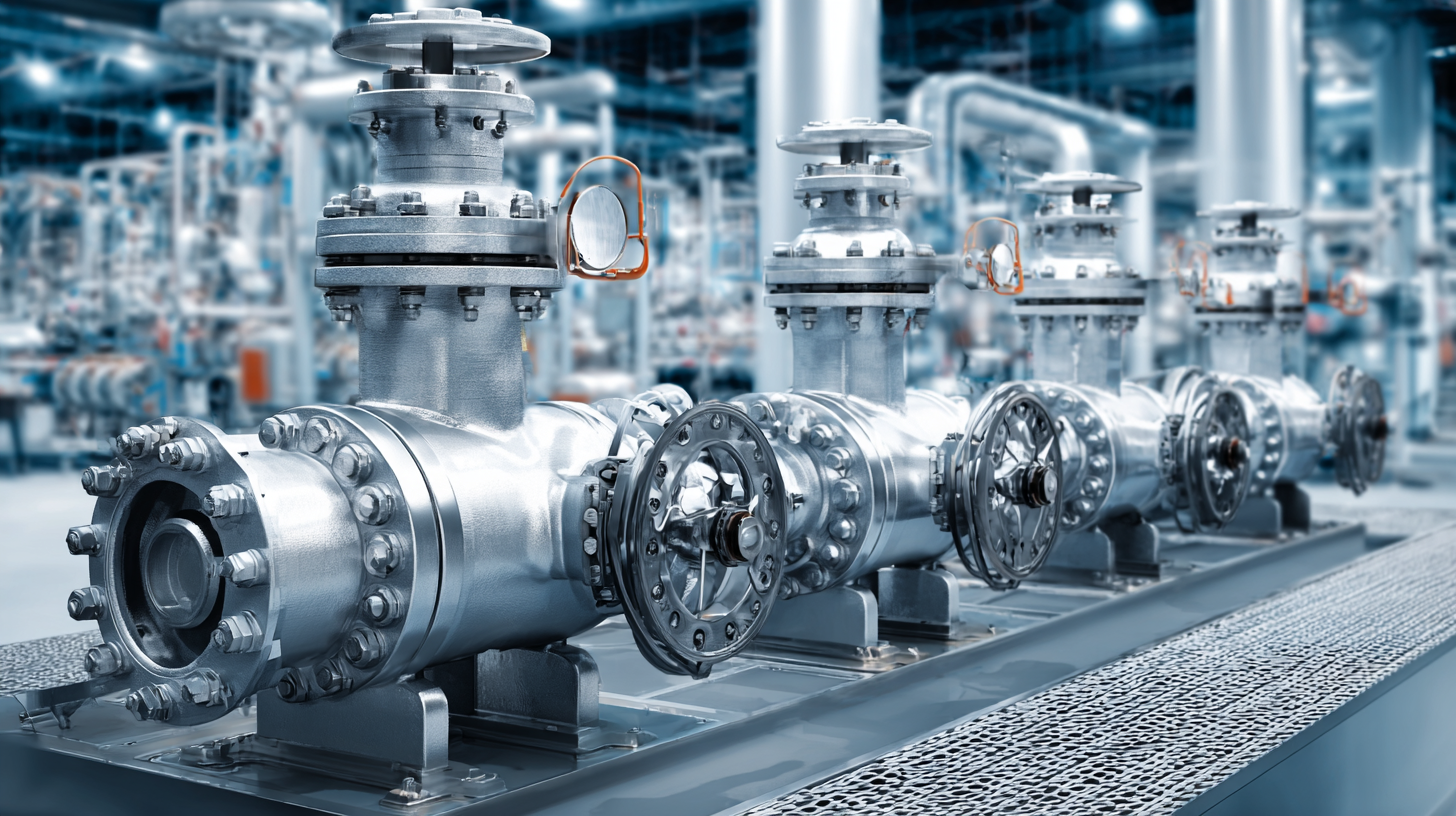

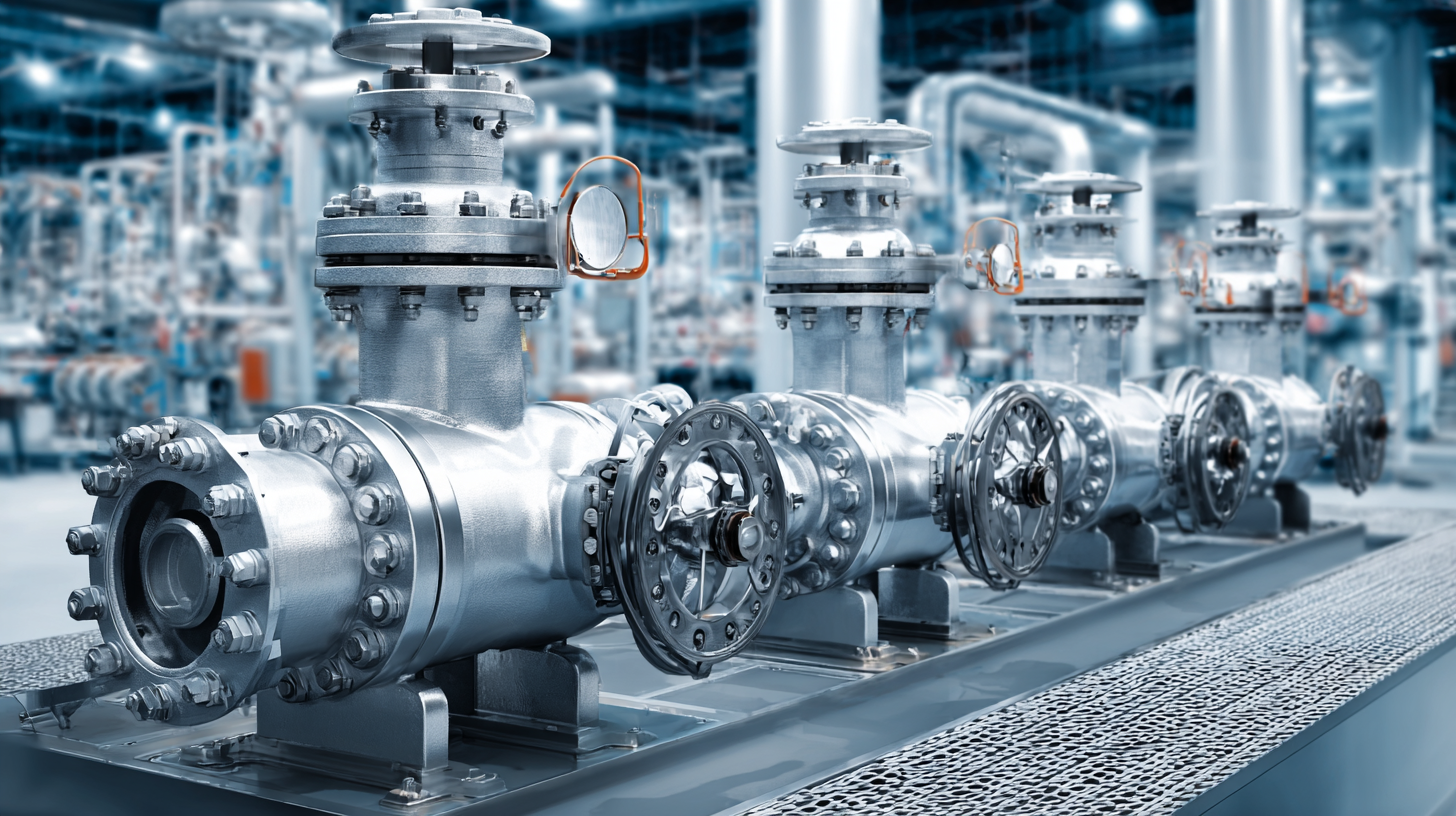

The Future of Industrial Valves: Innovations Shaping Global Procurement Strategies

As industries evolve and adapt to changing market demands, the role of Industrial Valves has become increasingly pivotal in global procurement strategies. According to a report by MarketsandMarkets, the industrial valves market is projected to reach USD 85.5 billion by 2026, growing at a CAGR of 4.8% during the forecast period. This growth is propelled by innovations in technology, such as smart valve systems and advanced materials that enhance efficiency and sustainability. In this landscape, procurement strategies must adapt to leverage these innovations, ensuring that organizations not only meet operational needs but also align with industry trends toward automation and efficiency. As we delve into the top strategies for optimizing procurement in the realm of industrial valves, it becomes crucial to understand the transformative impact of these advancements on supply chain dynamics and operational excellence.

Emerging Trends in Industrial Valve Technologies and Their Impact on Procurement

The industrial valve industry is undergoing rapid transformation driven by innovative technologies that are reshaping global procurement strategies. Emerging trends such as IoT-enabled valves and smart manufacturing practices are at the forefront of this evolution. These technologies not only enhance operational efficiency but also facilitate real-time monitoring and data analytics, allowing procurement professionals to make more informed decisions. IoT integration enables the collection of valuable data on valve performance and usage, leading to improved predictive maintenance and reduced downtime.

Additionally, the push for sustainability is prompting manufacturers to adopt eco-friendly materials and energy-efficient designs. Procurement strategies are increasingly aligning with environmental goals, emphasizing the importance of sourcing from suppliers committed to sustainable practices. This shift is not only beneficial for the environment but also supports long-term cost savings and enhanced corporate responsibility.

As industrial valves continue to evolve, procurement departments must stay agile and adapt to these innovations, ensuring they leverage the latest technologies to optimize their supply chains and meet the changing demands of the market.

The Role of Automation and IoT in Revolutionizing Valve Manufacturing

The emergence of automation and the Internet of Things (IoT) is revolutionizing valve manufacturing, reshaping not only production processes but also the broader landscape of industrial procurement strategies. Automation technologies streamline production lines, enhancing precision and efficiency in the manufacturing of valves. Robots and advanced machinery now handle tasks ranging from assembly to quality inspection, minimizing human error and reducing lead times. This shift not only cuts costs but also allows manufacturers to respond swiftly to market demands, catering to the rising complexity in industrial applications.

In parallel, the integration of IoT technology is providing unprecedented levels of connectivity and data analysis. Smart valves equipped with sensors can monitor performance in real-time, providing critical data that allows for predictive maintenance and optimized resource use. This connectivity facilitates greater transparency in the supply chain, enabling buyers to make informed procurement decisions based on real-time data. As manufacturers and suppliers harness these technologies, the future of industrial valves is marked by advanced capabilities that enhance operational efficiency and drive down costs, ultimately transforming global procurement strategies in the industry.

Sustainability and Eco-Friendly Practices in Global Valve Production

The industrial valve sector is undergoing a revolutionary transformation driven by sustainability and eco-friendly practices. According to a report by MarketsandMarkets, the global industrial valve market is expected to grow from USD 70.38 billion in 2021 to USD 88.78 billion by 2026, indicating a CAGR of 4.7%. This growth is largely attributed to increased regulatory pressures on manufacturers to adopt greener manufacturing processes. Industries are now prioritizing valve production methods that reduce energy consumption, waste generation, and harmful emissions, aligning with global sustainability goals.

To meet these demands, many valve manufacturers are investing in advanced technologies that enhance eco-efficiency. For instance, the adoption of innovative materials, such as bio-based composites and recycled metals, contributes to lowering the carbon footprint associated with valve production. A 2022 report by the International Energy Agency highlighted that implementing sustainable materials could reduce greenhouse gas emissions in manufacturing by up to 40%. Additionally, companies are integrating IoT solutions into valve systems, enabling real-time monitoring and optimizing resource usage, further solidifying sustainability as a key driver in modern procurement strategies within the industrial valve industry.

The Future of Industrial Valves: Innovations Shaping Global Procurement Strategies

This chart illustrates the projected percentage of investment in various innovative practices in the global valve industry, highlighting the importance of sustainability and eco-friendly practices in shaping procurement strategies.

The Influence of Global Supply Chain Dynamics on Valve Sourcing Strategies

As the global marketplace continues to evolve, supply chain dynamics play a crucial role in shaping sourcing strategies for industrial valves. The recent disruptions caused by the pandemic, geopolitical tensions, and fluctuating trade policies have compelled manufacturers and procurement professionals to reassess their approaches. Emphasizing local sourcing and developing strategic partnerships has become increasingly vital. Companies are now prioritizing suppliers who can provide not only quality but also reliability and responsiveness.

In addition to local sourcing, the integration of advanced technologies is revolutionizing how companies manage their valve procurement strategies. IoT and AI-driven data analytics are enabling companies to forecast demand more accurately and optimize inventory levels, thus reducing lead times and minimizing stockouts. By leveraging these technological advancements, businesses can navigate supply chain uncertainties more effectively, ensuring they remain agile in a fast-paced market. As innovations continue to reshape the industrial valve landscape, understanding global supply chain dynamics will be essential for developing resilient and sustainable sourcing strategies.

Case Studies: Successful Innovations in Industrial Valves from China and Beyond

The global landscape of industrial valves is rapidly evolving, with groundbreaking innovations driving procurement strategies across various sectors. One notable example comes from China, where a leading manufacturer developed a smart valve equipped with IoT technology, enabling real-time monitoring and management. This innovation not only enhances operational efficiency but also significantly reduces maintenance costs by predicting potential failures before they occur. Companies leveraging such technology can streamline their supply chain processes and make informed decisions, demonstrating the profound impact of smart solutions on procurement.

Beyond China, European companies are also making strides with their sustainable valve designs. A case study showcases a German manufacturer that introduced a series of eco-friendly valves made from recycled materials. These valves not only meet stringent environmental regulations but also appeal to businesses aiming for sustainability in their operations. By integrating sustainability into their product development, these companies are not only attracting environmentally conscious clients but also positioning themselves favorably as global markets increasingly prioritize green procurement. This shift towards innovative and sustainable solutions exemplifies how the industrial valve sector is adapting to meet contemporary challenges and changing demands.