7 Essential Reasons Your Business Needs a Reliable Valve Actuator

In today's rapidly evolving industrial landscape, the importance of efficient and reliable valve actuators cannot be overstated. According to a recent report by MarketsandMarkets, the global valve actuator market is projected to reach $5.8 billion by 2025, with a compound annual growth rate (CAGR) of 6.5% from 2020 to 2025. This growth underscores the critical role that valve actuators play in various industries, including oil and gas, water and wastewater management, and power generation. As businesses seek to enhance operational efficiency and reliability, the need for high-quality valve actuators becomes paramount. In this blog, we will explore seven essential reasons why investing in a reliable valve actuator is not just beneficial but necessary for your business's long-term success and competitiveness in the market.

The Role of Valve Actuators in Enhancing Operational Efficiency

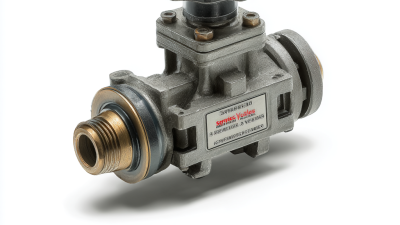

In the modern industrial landscape, enhancing operational efficiency is paramount, and valve actuators play a crucial role in achieving this goal. These devices control the opening and closing of valves, allowing for precise regulation of fluid flow and process control. By ensuring accurate responses to automated commands, valve actuators contribute significantly to reducing downtime and maintaining optimal performance across operations. This precision helps prevent costly leaks and errors, which can disrupt production and lead to financial losses.

Moreover, the integration of reliable valve actuators promotes seamless communication within automated systems. When paired with advanced control technology, they enable real-time monitoring and adjustments, enhancing responsiveness and adaptability to varying operational conditions. This capability is essential for industries like oil and gas, water treatment, and chemical processing, where any delay or mismanagement can have dire consequences. By investing in high-quality valve actuators, businesses can facilitate smoother workflows, lower operational costs, and ultimately increase their competitive edge in the market.

7 Essential Reasons Your Business Needs a Reliable Valve Actuator - The Role of Valve Actuators in Enhancing Operational Efficiency

| Reason |

Description |

Impact on Efficiency |

Cost Saving Potential |

| Precision Control |

Valve actuators provide exact control over fluid flow, enhancing process accuracy. |

Increased quality of end products. |

Reduced waste and rework costs. |

| Safety |

Reliable actuators prevent leaks and pressure build-ups, ensuring safe operations. |

Minimized risk of accidents. |

Avoidance of costly incident-related expenses. |

| Energy Efficiency |

Smart actuators optimize energy consumption by regulating flow based on demand. |

Lower energy costs and carbon footprint. |

Significant savings on energy bills. |

| Remote Operation |

Enables control from a distance, improving flexibility in operations. |

Faster response to system changes. |

Reduced manpower and associated costs. |

| Durability |

High-quality actuators withstand harsh environments, reducing maintenance needs. |

Longer operational lifespans. |

Lower maintenance and replacement costs. |

| Automation |

Integrates with control systems for automated processes, enhancing productivity. |

Streamlined operations with minimal human intervention. |

Increased profitability from optimized workflows. |

| Data Feedback |

Advanced actuators provide real-time data, aiding in quick decision-making. |

Improved process monitoring and adjustments. |

Reduced operational inefficiencies. |

How Reliable Valve Actuators Improve Safety and Reduce Risks

In today’s industrial landscape, safety and risk management are paramount, and reliable valve actuators play a crucial role in enhancing these aspects. These devices ensure that valves operate smoothly and efficiently, minimizing the potential for leaks and hazardous material releases. By incorporating reliable actuators into your system, you can significantly decrease the chances of safety incidents, protecting both your employees and the environment.

Moreover, reliable valve actuators can reduce risks associated with system failures. When actuators perform predictably, maintenance schedules can be improved, allowing for proactive repairs and replacements. This not only minimizes downtime but also curtails costly emergency interventions that often arise from unexpected breakdowns. Ultimately, the presence of dependable valve actuators fosters a safer working environment and promotes operational continuity, ensuring your business runs smoothly without the looming threat of accidents or disruptions.

Cost Savings: Investing in Quality Valve Actuators for Long-term Benefits

Investing in quality valve actuators is not just about ensuring reliable operations; it directly correlates with substantial cost savings over time. According to a report by MarketsandMarkets, the global valve actuator market is projected to reach $4.8 billion by 2025, driven predominantly by increasing demand for energy efficiency and automation across various industries. Businesses that prioritize quality valve actuators can benefit from reduced maintenance costs and enhanced operational efficiency, as high-quality actuators often have lower failure rates and longer lifespans.

Moreover, the lifecycle cost analysis indicates that investing in premium valve actuators can lead to a decrease in operational downtime. A study by the National Institute of Standards and Technology (NIST) highlighted that manufacturing facilities lose up to 5% of their production time due to equipment failures. By selecting robust actuators, companies can minimize these disruption costs, which can exceed thousands of dollars per hour. Hence, the initial investment in quality valve actuators is offset by the significant long-term savings and productivity enhancements they provide, reinforcing their essential role in modern businesses.

Improving Maintenance and Downtime Management with Reliable Actuators

In the increasingly competitive landscape of modern industry, the efficiency of maintenance and downtime management plays a crucial role in a business's success. According to a report by the International Society of Automation, companies can lose up to 20% of their annual revenue due to unplanned downtime, often caused by equipment malfunction. Investing in reliable valve actuators not only mitigates these risks but also streamlines maintenance processes. These actuators enhance operational reliability by providing consistent performance, which reduces the frequency of repairs and inspections, ultimately leading to lower operational costs.

Moreover, a study by ARC Advisory Group highlights that predictive maintenance strategies, supported by advanced actuator technology, can decrease downtime by as much as 30%. Reliable valve actuators equipped with smart technology can communicate real-time data and performance metrics, enabling proactive maintenance scheduling rather than reactive firefighting. This shift not only prolongs the lifespan of equipment but also ensures that production processes run smoothly, contributing to improved throughput and efficiency. By prioritizing the integration of dependable actuators, businesses can significantly enhance their maintenance strategies and achieve better overall asset management.

7 Essential Reasons Your Business Needs a Reliable Valve Actuator

Regulatory Compliance: Why Your Business Needs Dependable Valve Solutions

When it comes to regulatory compliance, having dependable valve solutions is not just a preference; it's a necessity for businesses operating in regulated industries. Regulatory frameworks often dictate stringent standards for safety, environmental protection, and operational efficiency. A reliable valve actuator plays a pivotal role in ensuring that your systems function correctly, preventing leaks and failures that could lead to non-compliance and hefty fines.

Moreover, the integration of reliable valve actuators into your processes ensures that your operations remain consistent and predictable. This reliability minimizes the risk of unexpected downtime, which can be costly both financially and in terms of reputation. By investing in high-quality valve solutions, your business can better navigate the complexities of regulation, ultimately fostering trust with stakeholders, customers, and regulatory bodies alike. In this dynamic landscape, a dependable actuator is not merely an accessory; it is a critical component in sustaining compliance and operational integrity.