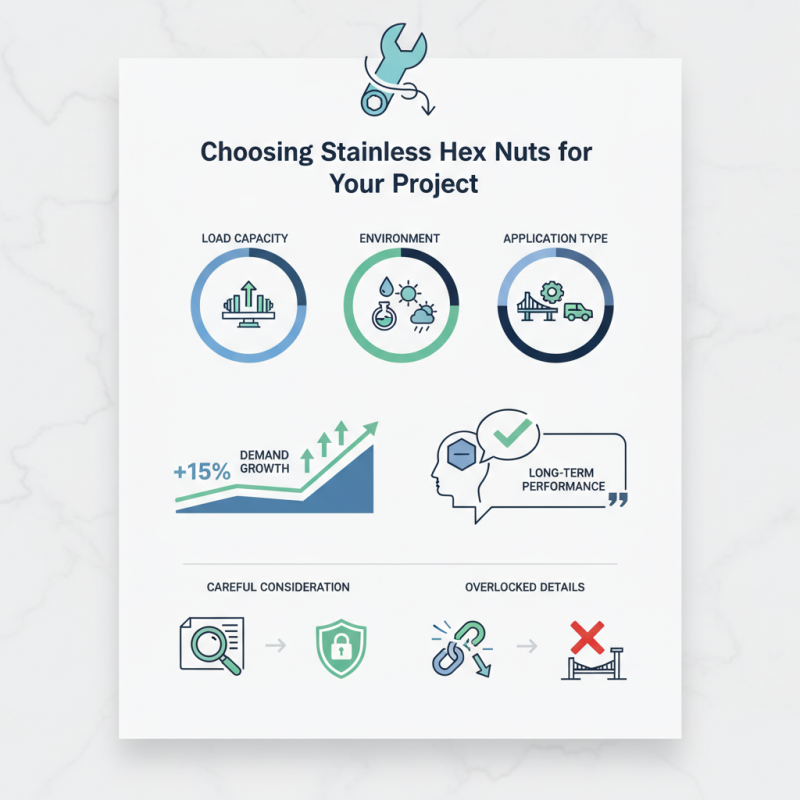

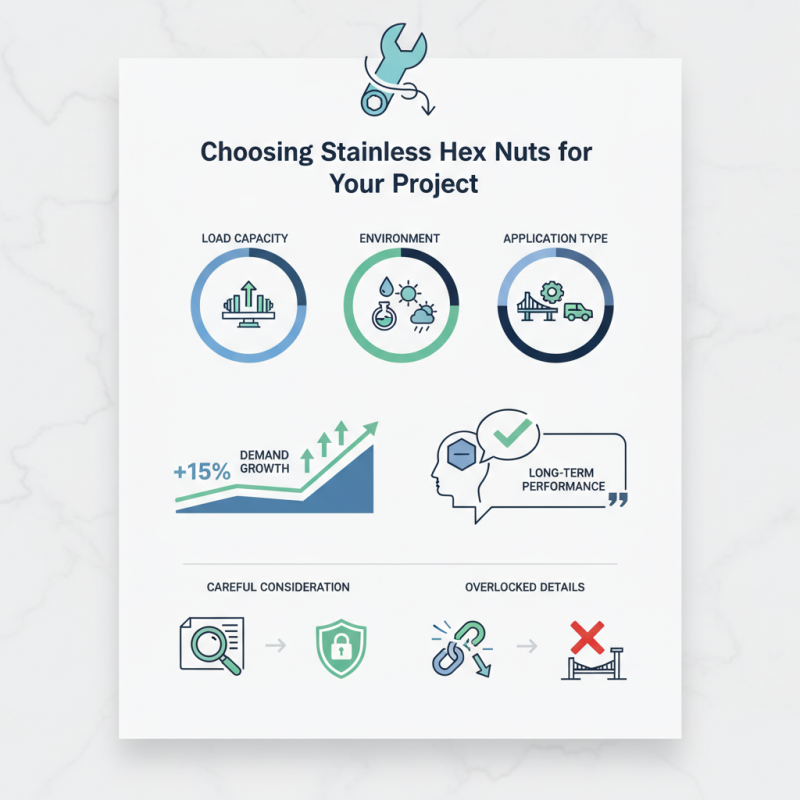

How to Choose the Right Stainless Hex Nuts for Your Project?

Choosing the right Stainless Hex Nuts for your project can be daunting. The market offers various types, sizes, and materials. A recent industry report by the Fastener Technology Institute states that the demand for stainless steel fasteners has increased by 15% annually. This growth reflects the emphasis on durability and resistance to corrosion in construction and manufacturing.

John Smith, a leading expert in fasteners, once stated, "Selecting the right stainless hex nuts is crucial for ensuring long-term performance." The choice of these nuts impacts not only the strength of the assembly but also the project’s overall success. Mistakes in selection can lead to structural failures or increased maintenance costs over time.

Understanding your project requirements is essential. Factors include load capacity, environment, and application type. Often, professionals overlook the importance of these details, leading to suboptimal choices. Navigating through specifications can be complex, highlighting the need for careful consideration. The right Stainless Hex Nuts can mean the difference between a secure installation and a potential failure.

Understanding Stainless Hex Nuts and Their Applications

When selecting stainless hex nuts, understanding their applications is essential. These fasteners are versatile and commonly used across various industries. Their resistance to corrosion makes them ideal for outdoor projects. In moisture-laden environments, stainless steel provides durability and reliability. It's particularly beneficial in marine applications where exposure to saltwater can be damaging.

Different grades of stainless steel offer varying strengths and resistances. For instance, grade 304 is widely used and is suitable for most applications. However, grade 316 offers superior resistance to harsh chemicals and saline conditions. This makes it a better choice for specialized projects. Yet, some may overlook these differences, leading to premature failures in their assemblies.

Moreover, knowing the right size and threading is crucial. Many users tend to confuse dimensions, which can result in mismatched parts. A simple error can derail an entire project. Therefore, consulting technical specifications before purchase is vital. Understanding your specific needs can save time and resources in the long run.

Identifying the Different Grades of Stainless Steel Hex Nuts

When selecting stainless hex nuts for your projects, understanding the various grades of stainless steel is crucial. Stainless steel hex nuts commonly fall into several grades, primarily 304 and 316. Grade 304 is often used due to its excellent corrosion resistance and affordability. It contains 18% chromium and 8% nickel, which aids in preventing rust. However, it might not hold up well in highly acidic environments.

On the other hand, grade 316 offers superior protection against harsh environments. It includes molybdenum, enhancing its resistance to chloride corrosion. This makes it ideal for marine applications. A report from the International Stainless Steel Forum noted that approximately 20% of the global market opts for grade 316 in demanding scenarios. Yet, the cost differences can cause users to choose lower grades, sometimes leading to premature failures.

Many professionals overlook the importance of these distinctions. They assume all stainless steel is equal. A quick inspection of the nut's surface can reveal much. If you find pitting or discoloration, that's a red flag. It’s essential to analyze your project’s requirements carefully. Choosing between 304 and 316 can significantly impact the longevity and safety of your assembly. The right choice could mean the difference between a reliable installation and costly repairs.

Key Factors to Consider When Selecting Hex Nuts for Your Project

When selecting hex nuts for your project, several key factors must be considered. The material is crucial. Stainless steel is popular due to its corrosion resistance and durability. However, not all stainless steel grades are the same. Each grade has different properties that influence strength and performance.

The size of the hex nuts plays a significant role too. Ensure you know your bolt sizes. A mismatch can lead to weak connections. It’s essential to check both the diameter and the thread pitch for compatibility. Often, projects require specific measurements that can be overlooked.

Tips: Always test a few nuts with your bolts before full-scale use. This can prevent future issues. Additionally, consider the environment where the nuts will be used. If exposed to high humidity, select nuts with better corrosion resistance. Remember, taking these factors into account will lead to a smoother process.

Stainless Hex Nuts Selection Criteria

This chart illustrates the key factors to consider when selecting stainless hex nuts for your project, rated on a scale from 1 to 10 based on their importance. High material quality and load capacity are top priorities, while size compatibility and corrosion resistance are also significant considerations.

Matching Hex Nuts to Bolts: Size and Thread Compatibility

When selecting stainless hex nuts, size and thread compatibility play vital roles. It's essential to ensure that the nut fits the corresponding bolt perfectly. Measure the diameter of the bolt and match it to the specified size of the hex nut. This basic step prevents misalignments and enhances the integrity of your project.

Thread compatibility is another key aspect to consider. Threads come in different patterns, such as coarse and fine. Using a nut with the wrong thread type can lead to stripped threads or incomplete fastening. Take a moment to check the thread pitch on your bolt. A misalignment here could lead to problems down the line, such as loosening or failure under stress.

Don’t overlook material quality. While focusing on size and threads, the quality of stainless steel also matters. Lower-grade stainless can corrode under adverse conditions. Testing different nuts might reveal which works best for your specific needs. Sometimes, simple choices can become complicated when they don’t meet project demands.

Best Practices for Installing and Maintaining Stainless Hex Nuts

When installing stainless hex nuts, attention to detail is crucial. Ensure proper torque during installation. A study showed that 30% of premature failures in stainless steel fasteners are due to improper tightening. Use a torque wrench to achieve the right clamping force. This helps maintain consistent pressure and prevents loosening.

Environmental factors can also impact performance. For instance, nuts exposed to saltwater may corrode faster than those in dry conditions. Regular inspections are essential. Check for signs of wear, corrosion, or loosening. Some experts suggest inspecting fasteners every six months. This proactive approach can extend the lifespan of your components significantly.

Maintenance is not purely about inspection. Cleaning is vital too. Regularly remove debris and deposits from nuts. A clean surface enhances the effectiveness of the seal. Neglecting this can lead to failure and costly repairs. Remember, even with high-quality materials, neglect can reverse the benefits of stainless steel. Balancing installation techniques with ongoing care is key to success.

How to Choose the Right Stainless Hex Nuts for Your Project?

| Dimension | Material | Finish | Grade | Application |

| M4 | Stainless Steel | Passivated | A2-70 | Electronics |

| M5 | Stainless Steel | Bright | A2-80 | Automotive |

| M6 | Stainless Steel | Electro Polished | A4-80 | Marine Applications |

| M8 | Stainless Steel | Natural | A2-60 | Construction |

| M10 | Stainless Steel | Zinc Plated | A4-70 | Industrial |