How to Choose the Right Pressure Valves for Your Industry Needs

In various industries, selecting the appropriate pressure valves is crucial to ensure operational efficiency and safety. According to a recent market analysis by Research and Markets, the global pressure valve market is expected to reach $13.5 billion by 2026, growing at a CAGR of 5.1% during the forecast period. This growth is driven by the increasing demand for automated systems and the expansion of the oil and gas sector, which emphasizes the need for reliable pressure control. However, with a multitude of options available, it can be challenging to determine which pressure valves best suit specific operational requirements. Key factors such as material compatibility, pressure ratings, and environmental conditions must be evaluated carefully. This guide will provide essential tips for industry professionals, enabling them to make informed decisions that enhance the safety and efficiency of their processes while optimizing costs.

Understanding Pressure Valve Types: A Comprehensive Guide for Industrial Applications

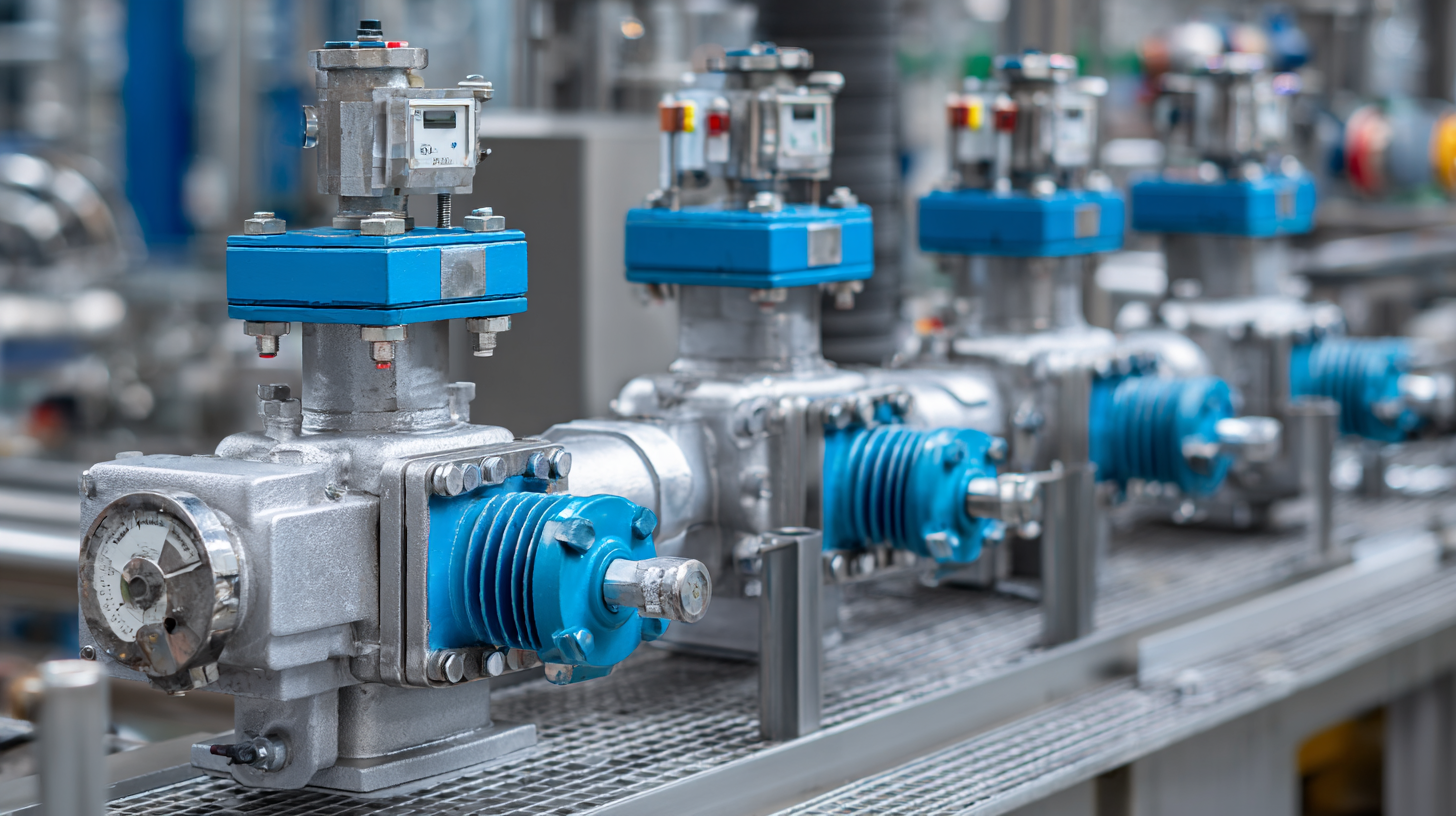

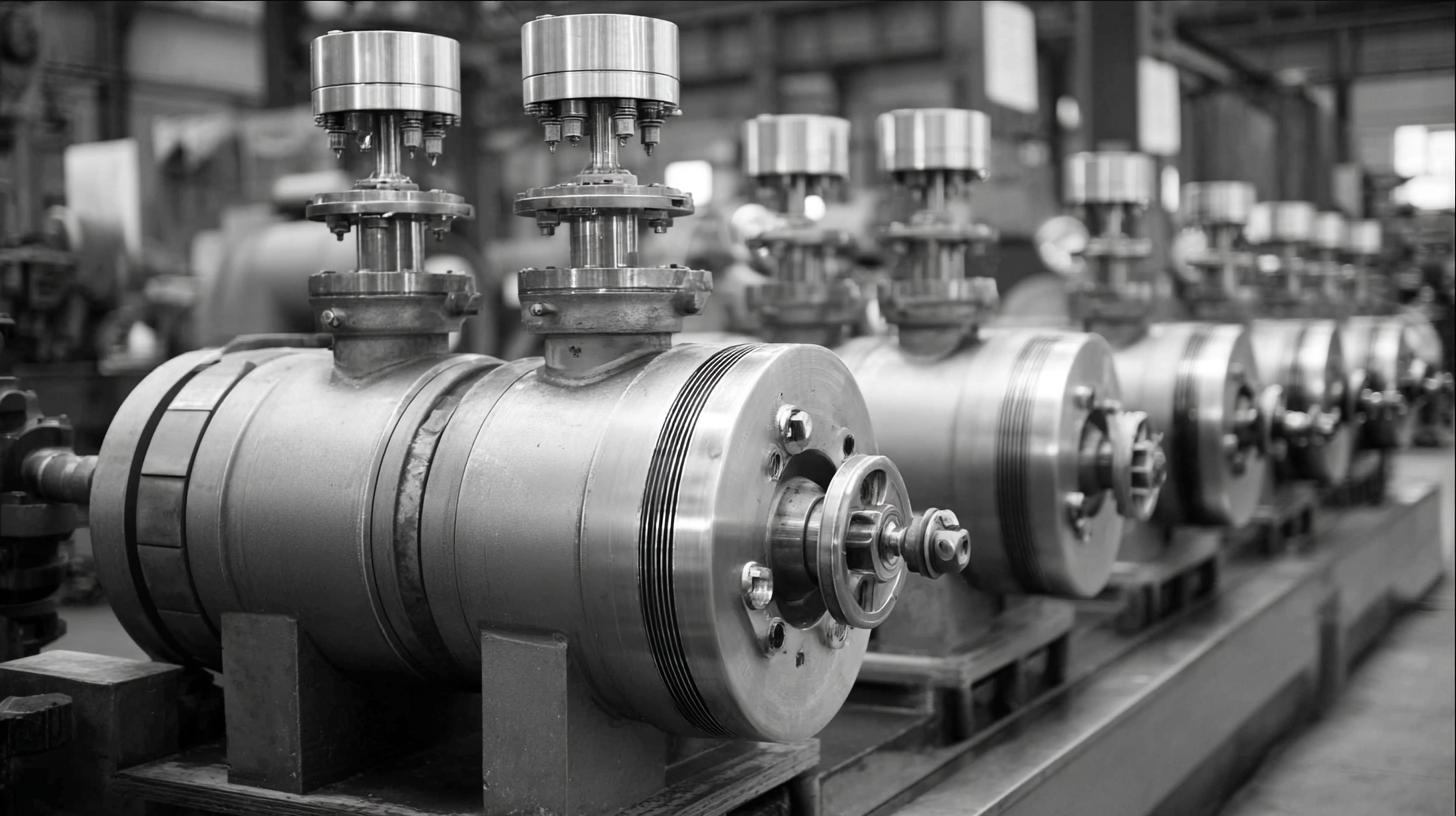

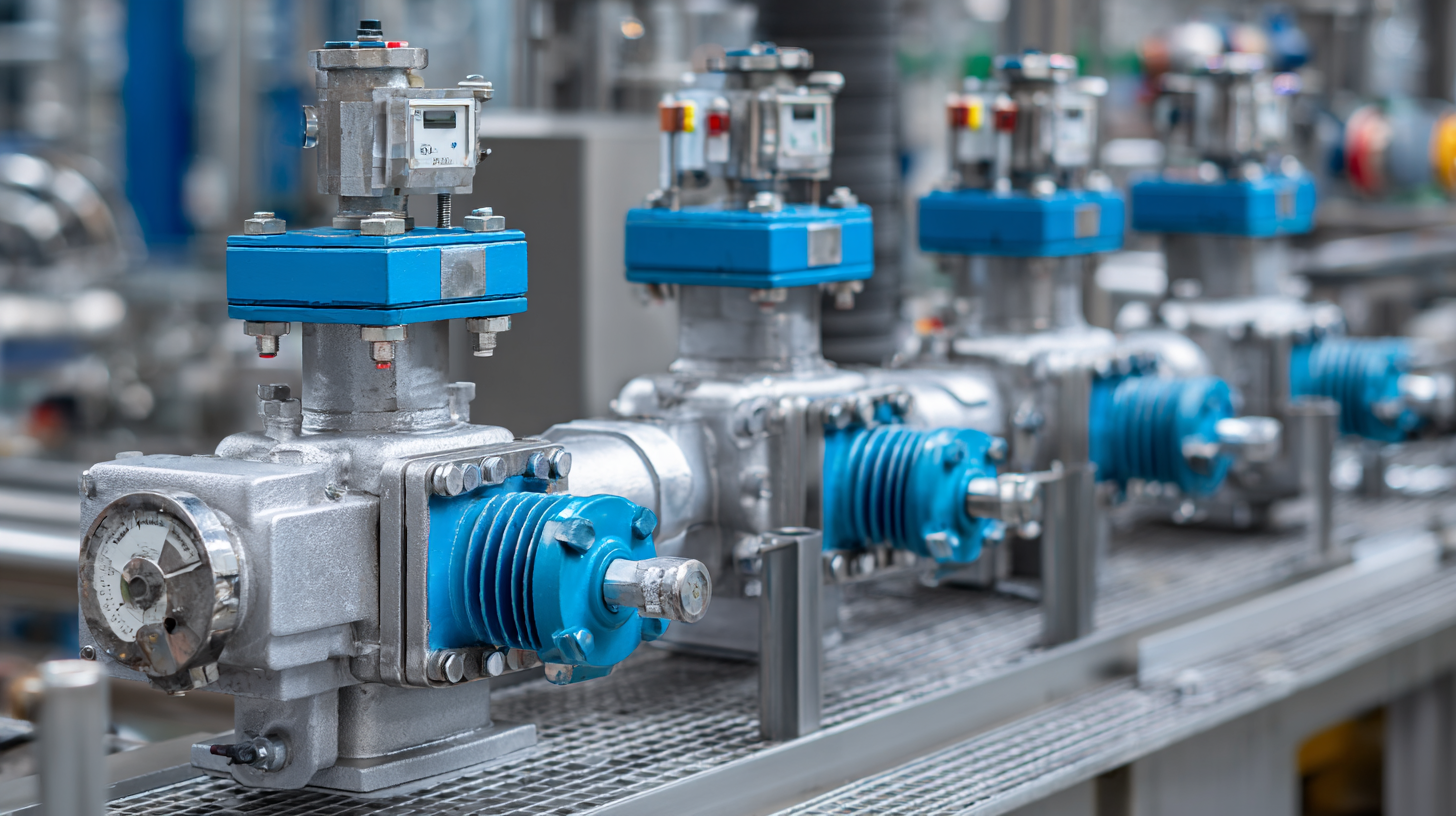

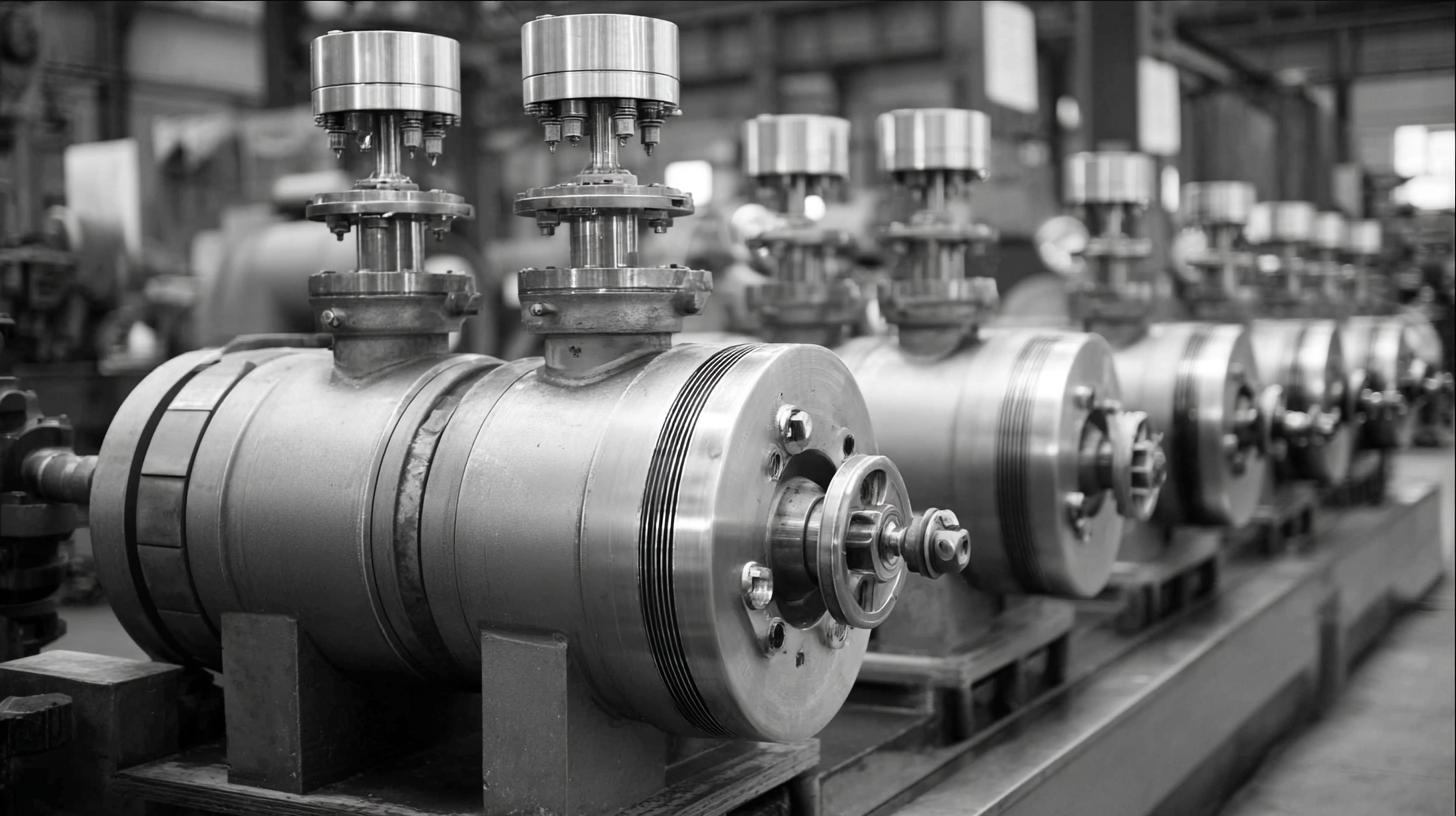

When selecting the appropriate pressure valves for industrial applications, it’s essential to understand the various types available and their specific functions. Common types include relief valves, check valves, and control valves. Relief valves prevent system overpressure by releasing excess fluid, while check valves ensure unidirectional flow, preventing backflow. Control valves, on the other hand, regulate flow and pressure in response to control signals. Each valve type plays a critical role in enhancing operational efficiency and safety within industrial systems.

**Tips:** When choosing a pressure valve, always consider the media type, temperature, and pressure ranges of your application. For instance, corrosive fluids may require specialized materials such as stainless steel or plastic. Additionally, ensure that the valve's size matches your system specifications to avoid pressure drops and inefficiencies.

Another key consideration is the operational environment. High temperatures or hazardous conditions may necessitate the use of valves designed to withstand extreme situations. It’s advisable to consult industry standards and seek input from knowledgeable suppliers to ensure you select the most suitable valve for your specific needs. Investing time in understanding your options can lead to significant long-term benefits in safety and performance.

Pressure Valve Types and Their Applications

Key Industry Standards and Regulations Impacting Pressure Valve Selection

When selecting pressure valves for specific industry needs, understanding the key industry standards and regulations is crucial. Regulatory bodies often impose strict guidelines to ensure safety, efficiency, and compliance with industry norms. For instance, in sectors such as healthcare and manufacturing, adherence to federal requirements is vital. These regulations can dictate specifications for pressure valves, influencing material choices, performance metrics, and operational limits. Failure to comply can result in severe penalties and impact operational integrity.

Additionally, organizations such as the ISA provide standards that streamline automation processes across various industries, enhancing safety and efficiency. Compliance with these standards not only mitigates risks but also improves the overall functionality of pressure valves in automated systems. As industries continue to evolve, it is essential to keep abreast of changing regulations and technological advancements to ensure that the selected pressure valves meet both compliance requirements and operational demands.

Evaluating Performance Metrics: Flow Rate, Pressure Range, and Temperature Tolerance

When selecting pressure valves for industrial applications, understanding key performance metrics is essential. The flow rate is a crucial factor as it determines how much fluid can pass through the valve in a given time frame. Industries with high fluid throughput will need valves designed to accommodate large flow rates without compromising performance. It is vital to match the valve's flow capacity with the requirements of the system to ensure efficiency and avoid potential bottlenecks.

Another critical metric is the pressure range. Different industrial environments operate under varying pressure conditions, and choosing a valve that can function effectively within these limits is key to maintaining system integrity. Operating a valve outside its specified pressure range can lead to failure, increased maintenance costs, or even safety hazards. Additionally, temperature tolerance must be considered, as many industries deal with fluids at extreme temperatures. A valve that cannot withstand the specific thermal conditions of its environment may degrade over time, leading to leaks or breakdowns. Evaluating these metrics carefully ensures that the selected valves will perform reliably and meet the operational demands of the industry.

Material Selection Criteria: Corrosion Resistance and Durability for Long-Term Use

When selecting pressure valves for industrial applications, material selection is critical, particularly regarding corrosion resistance and durability. Industries often face harsh environments that exacerbate material degradation, making it essential to choose materials that can withstand such conditions over the long term. For example, titanium alloys, such as commercially pure titanium and Ti-6Al-4V, have demonstrated remarkable corrosion resistance, contributing to their clinical success in dental implants. This aspect highlights the importance of material properties that ensure longevity and reliability under operational stresses.

Recent advancements in material science also emphasize the need for comprehensive corrosion prevention strategies. For instance, the evaluation of materials used in bipolar plates for PEM water electrolysis stresses the significance of mitigating corrosion to enhance performance efficiency. Additionally, studies focusing on alternative materials, such as glass fiber reinforced polymer (GFRP) and its structural performance compared to traditional metals, reveal ongoing efforts to develop sustainable and resilient solutions. The insights from diverse industries on material performance under corrosive conditions are invaluable for making informed decisions when choosing pressure valves.

Cost-Benefit Analysis: Balancing Initial Investment and Long-Term Efficiency in Pressure Valves

When selecting pressure valves for industrial applications, understanding the balance between initial investment and long-term efficiency is crucial. The upfront costs of high-quality pressure valves may seem daunting; however, their reliability and performance can lead to significant cost savings over time. Cheaper alternatives may require more frequent replacements and maintenance, ultimately driving up operational expenses. Therefore, conducting a thorough cost-benefit analysis is essential to make informed decisions that align with long-term efficiency goals.

In addition to direct costs, factors such as energy consumption, durability, and maintenance requirements should be evaluated. Valves that offer greater efficiency in reducing energy loss and handling operational demands can yield higher returns on investment. Additionally, selecting valves designed for longevity and ease of maintenance can minimize downtime and labor costs. By prioritizing long-term efficiency in valve selection, industries can create a more sustainable operation while ensuring their investment pays off in the long run.

How to Choose the Right Pressure Valves for Your Industry Needs - Cost-Benefit Analysis: Balancing Initial Investment and Long-Term Efficiency in Pressure Valves

| Valve Type |

Initial Cost ($) |

Maintenance Cost/Year ($) |

Expected Lifespan (Years) |

Efficiency Rating (%) |

Total Cost Over Lifespan ($) |

| Ball Valve |

150 |

10 |

10 |

90 |

300 |

| Gate Valve |

200 |

15 |

12 |

85 |

380 |

| Globe Valve |

180 |

20 |

15 |

80 |

480 |

| Check Valve |

120 |

12 |

10 |

88 |

240 |