Why Should You Choose Automatic Valves for Your System?

In the world of industry, the choice of valves is crucial. Automatic valves are becoming increasingly popular in various systems. According to Dr. Emily Carter, a renowned expert in automation technology, "Automatic valves enhance efficiency and safety in operations." This highlights their importance in modern systems.

Automatic valves offer precise control over fluid flow. They minimize human involvement, which reduces the chance of error. This type of valve can react instantaneously to changes in pressure or flow. Their reliability is a key reason why many industries favor them over manual options.

However, not all automatic valves are created equal. Some may fail to operate efficiently under certain conditions. Choosing the right automatic valve requires careful consideration of specific system needs. Understanding the application is essential to maximize the benefits of these valves. Industry professionals must remain vigilant and continually assess their valve choices for optimal performance.

Benefits of Automatic Valves in Fluid Control Systems

Automatic valves play a critical role in fluid control systems. These valves enhance efficiency and safety. Research shows that automatic valves can improve system efficiency by over 30%. This reduction in energy consumption not only lowers operational costs but also benefits the environment. In a world striving for sustainability, every little bit helps.

Moreover, automatic valves reduce human error. A report from the Fluid Control Institute indicates that 70% of mishaps in fluid systems are due to manual operation failures. By integrating automation, operators can minimize risks. The system automatically adjusts to changes in pressure and flow, ensuring optimal performance. This can be vital in industries where safety is paramount.

Despite these advantages, some challenges remain. The upfront investment can be significant. Not all systems may see an immediate return on investment. Ongoing maintenance and regular checks are still necessary to avoid failures. Thus, understanding the costs and benefits is essential for a successful implementation. Balancing the need for automation with practical considerations is a continuous journey for many industries.

Types of Automatic Valves and Their Applications

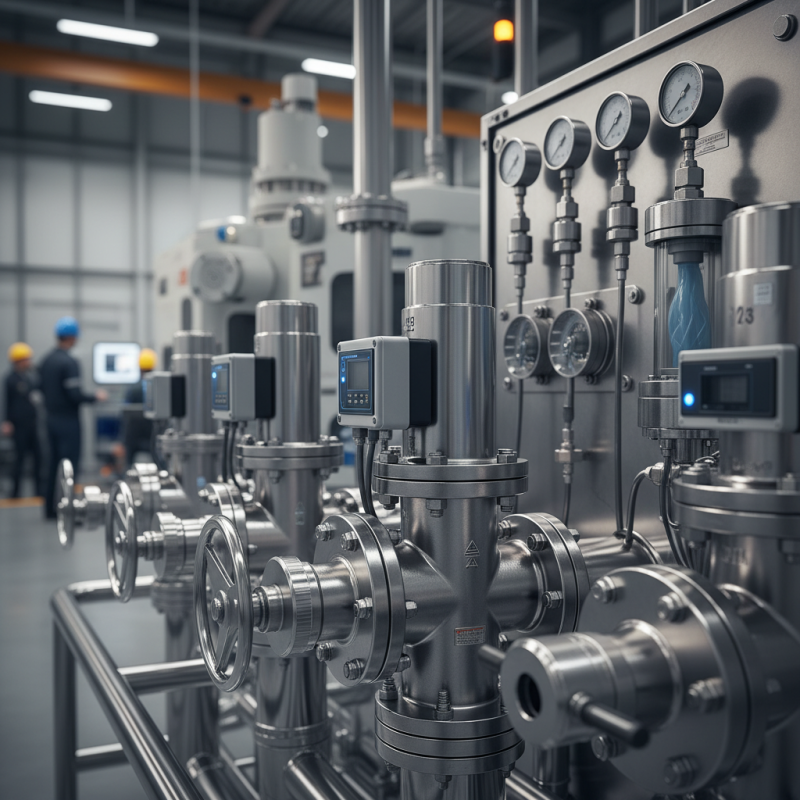

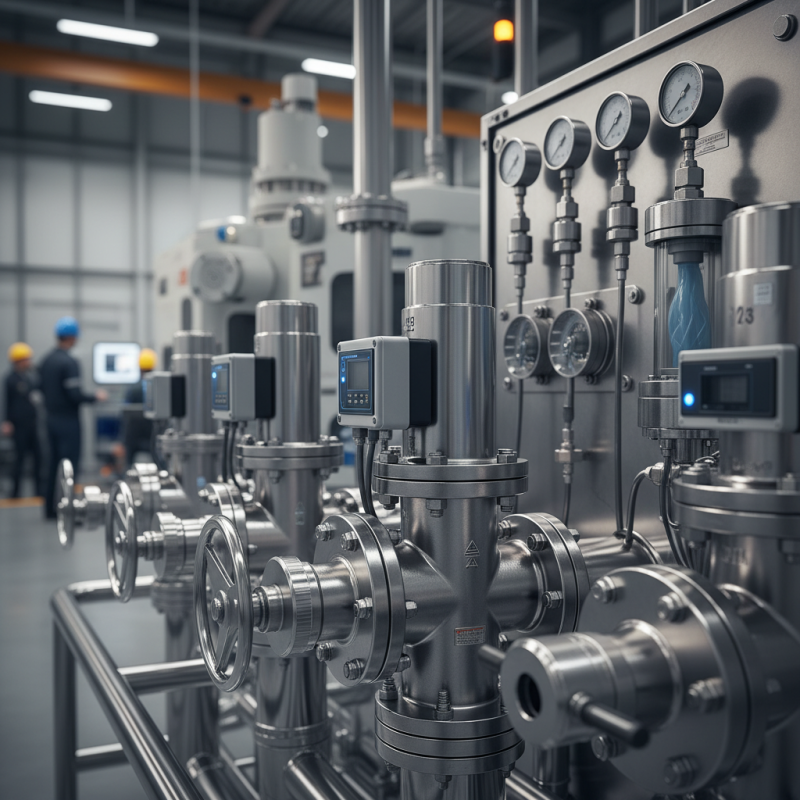

Automatic valves are crucial in many systems. They ensure efficiency and safety in operations. Various types of automatic valves serve different applications across industries. For instance, solenoid valves are widely used in fluid control systems. These valves can open and close quickly, making them ideal for applications that require precise flow control.

Another important type is the pneumatic valve. Pneumatic valves are often used in manufacturing setups. They operate using compressed air and are reliable for automating processes. According to industry reports, pneumatic systems are estimated to account for over 15% of factory automation systems. This highlights their relevance and efficiency.

Hydraulic valves are also significant in heavy machinery applications. They are designed to handle high pressure. The Global Hydraulic Valve Market is projected to grow steadily. By 2025, it is expected to reach approximately $8 billion, driven by increasing demand in construction and manufacturing sectors. However, automatic valves can suffer from wear and require regular maintenance. Understanding which type suits your system best is essential for optimal performance.

Why Should You Choose Automatic Valves for Your System? - Types of Automatic Valves and Their Applications

| Type of Automatic Valve |

Application |

Advantages |

Common Materials |

| Ball Valve |

Water Supply Systems |

Quick Operation, Low Pressure Drop |

Brass, Stainless Steel |

| Gate Valve |

Oil and Gas Pipelines |

Minimal Flow Resistance, Full Shutoff |

Cast Iron, Bronze |

| Globe Valve |

Steam and Water Systems |

Good Flow Regulation |

Stainless Steel, PVC |

| Check Valve |

Backflow Prevention in Pumps |

Automatic Operation, Prevents Backflow |

Brass, PVC |

| Butterfly Valve |

HVAC Systems |

Compact Size, Low Torque Requirement |

Aluminum, Stainless Steel |

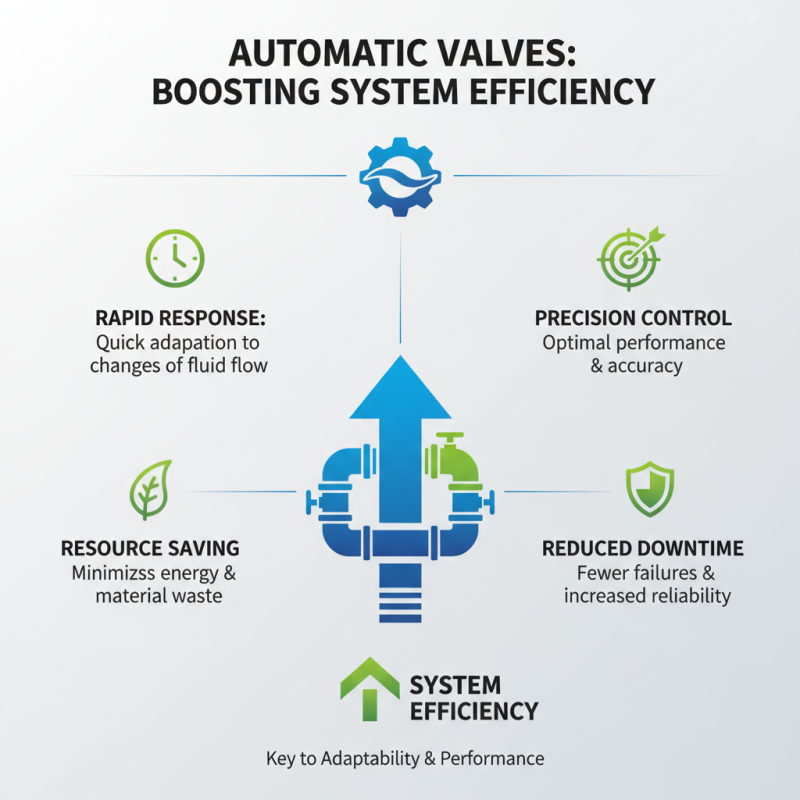

How Automatic Valves Improve System Efficiency

Automatic valves play a crucial role in enhancing system efficiency. They respond quickly to changes, allowing for better control of fluid flow. This adaptability minimizes waste in energy and resources. In systems where precision is key, automatic valves provide the responsiveness needed for optimal performance. Systems equipped with these valves often experience fewer failures and downtime.

Tips: Regular maintenance of automatic valves is essential. Even the best systems can falter without proper care. Watch out for signs of wear. A small problem can lead to significant inefficiencies if overlooked.

In many cases, users overlook the importance of selecting the right valve type. Compatibility with existing systems can be a tricky affair. Some valves may seem ideal but can lead to operational issues if not properly matched with system needs. Assessing your system requirements before making a purchase is vital. Missteps in this choice can lead to frustrating results.

Every system has its unique challenges. Continuous feedback from usage helps in identifying areas for improvement. Users might hesitate to invest in automation due to initial costs. However, the long-term benefits often outweigh the upfront expenses. By staying proactive, efficiency can be optimized, leading to smoother operations.

Factors to Consider When Choosing Automatic Valves

When considering automatic valves for your system, a few key factors demand attention. Start with the intended application. Different systems require various functionalities. For instance, a simple water system might need a straightforward valve, while a chemical plant requires a more complex solution. Knowing your system's demands is crucial and often underestimated.

Next, assess the valve material. Corrosion resistance is vital, especially in harsh environments. Using steel or specific plastics can drastically enhance durability. Also, consider temperature ranges. High temperatures may require special components. Many people overlook this, leading to early failure of the valves.

Another aspect is the control mechanism. Electric actuators offer precision, while pneumatic types offer speed. What’s best for you depends on your specific needs. Sometimes, people opt for cheaper options, which may not serve well in the long run. Reflect on balance between cost and performance. It’s a fine line to walk, but critical for system reliability.

Common Challenges and Solutions in Automatic Valve Implementation

Automatic valves offer numerous advantages in various systems, including precise control and reduced human error. However, implementing these valves can present challenges. Common issues include incorrect installation and inadequate training for personnel, leading to system inefficiencies. A recent industry report highlighted that around 30% of automatic valve failures stem from improper mounting. This emphasizes the need for diligent installation practices.

Tips: Regular training sessions can significantly enhance employee skills in this area. Consider practical workshops where individuals can practice with the valves first-hand. Understanding the mechanics behind automatic valves is crucial.

Another challenge is maintenance. Automatic valves require periodic checks and updates. Neglecting maintenance can lead to downtime. A study found that about 20% of maintenance costs are linked to valve management. This shows that consistent upkeep is vital for optimum functioning.

Tips: Establish a maintenance schedule to avoid costly repairs. Utilize digital monitoring tools for real-time assessments. These tools can help identify issues before they escalate.