Center Bearing Maintenance Tips for Optimal Performance?

Center Bearing systems play a crucial role in vehicle dynamics. Proper maintenance ensures optimal performance and longevity. Neglecting these components can lead to costly repairs and safety issues.

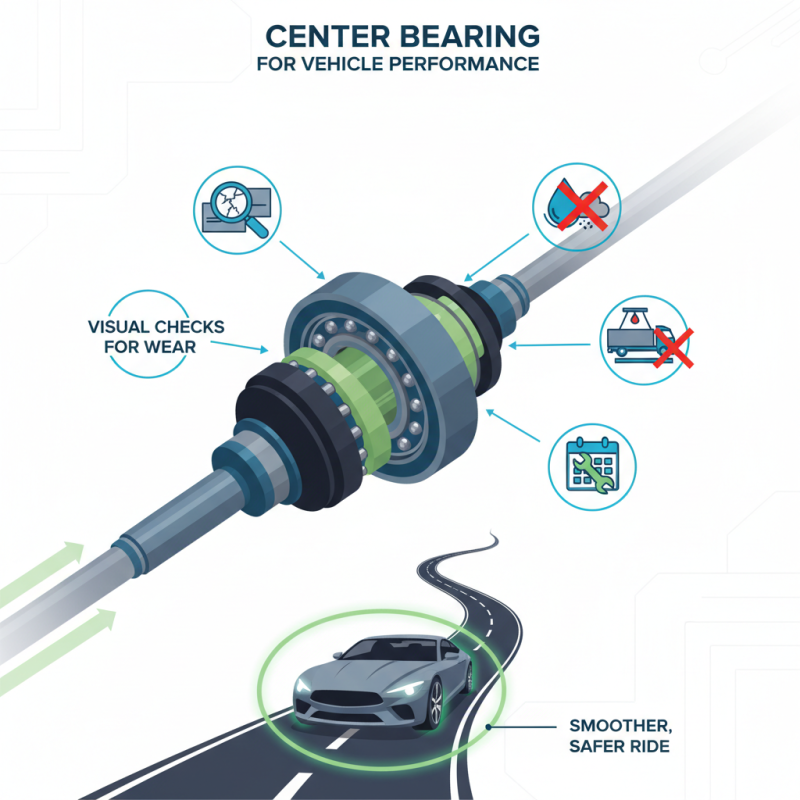

Regular checks and servicing are vital for a well-functioning Center Bearing. Visual inspections should occur frequently. Look for signs of wear, such as cracks or misalignment. These small details can save you from bigger problems.

Consider the environment where your vehicle operates. Dust and moisture can impact the Center Bearing's performance. Reflect on your usage patterns. Are you overloading your vehicle? Each of these factors influences the longevity of the bearing. Consistent maintenance habits create a smoother, safer ride.

Importance of Center Bearing in Vehicle Performance

The center bearing plays a critical role in vehicle performance. It supports the driveshaft and allows it to rotate smoothly. This component ensures proper alignment and minimizes vibration during vehicle operation. According to industry reports, improper center bearing maintenance can lead to up to a 30% decrease in efficiency. If this part fails, it can result in costly repairs or even accidents.

A well-maintained center bearing reduces wear on the drivetrain. Regular inspections can identify early signs of damage. Addressing these issues promptly can improve the lifespan of the car. On average, drivers are recommended to check the center bearing every 30,000 miles. However, many neglect this crucial maintenance step. Noticing unusual noises or vibrations is essential, as these are often warning signs of a failing bearing.

Neglecting the center bearing can result in significant issues. Increased fuel consumption is one of the hidden costs. A poorly functioning bearing can waste fuel, increasing operating expenses. In fact, it may lead to a 5-10% drop in fuel efficiency over time. By reflecting on these common mistakes, drivers can better understand the importance of proactive center bearing maintenance. It’s about keeping the vehicle performing at its best.

Signs of Wear and Tear in Center Bearings

Center bearings play a crucial role in drive shafts. However, wear and tear over time can significantly reduce their effectiveness. Recognizing early signs of deterioration is vital for maintaining optimal performance. Common indicators include unusual vibrations, which may suggest misalignment or imbalance. A study by the Society of Automotive Engineers found that 30% of all drive shaft failures relate to bearing issues. This highlights the importance of vigilance.

Another sign of wear is noise. If you hear grinding or clunking sounds, it could indicate that the lubrication inside the bearing is failing. Regular inspections are key to catching these issues before they escalate. According to maintenance reports, excessive heat buildup can also signal trouble. Bearings operate best within a specific temperature range, typically between 70°F and 200°F. Exceeding these limits can lead to premature failure.

Furthermore, visible damage around the center bearing is concerning. Cracks or corrosion can compromise performance. A comprehensive analysis from the International Mechanical Engineering Society revealed that proper maintenance could extend bearing life by up to 50%. Regular checks and timely interventions are essential. Identifying these signs early can save both time and costs in the long run. Ignoring them may lead to unexpected breakdowns and repairs.

Center Bearing Maintenance Tips for Optimal Performance

| Maintenance Tip | Signs of Wear and Tear | Recommended Action |

| Regular Inspection | Unusual noises during operation | Check for alignment issues |

| Lubrication | Reduced performance | Apply appropriate lubricant |

| Vibration Analysis | Excessive vibrations | Conduct technical assessment |

| Alignment Check | Uneven wear patterns | Realign components |

| Temperature Monitoring | Overheating | Inspect for lubrication or installation issues |

Preventive Maintenance Tips for Center Bearings

Center bearings are crucial for the smooth operation of any mechanical system. Proper preventive maintenance significantly extends their lifespan. According to industry reports, over 30% of bearing failures result from inadequate maintenance. Regularly checking the center bearings can save costs and downtime.

Tip 1: Regularly inspect for wear and tear. Look for signs of corrosion or unusual noise. These can indicate impending failure. Small details can save you from larger issues later.

Tip 2: Lubrication is key. Use the correct type of lubricant and apply it at recommended intervals. Proper lubrication reduces friction and heat build-up, prolonging bearing life.

Tip 3: Monitor operating conditions. High temperatures or excessive vibration can lead to premature bearing damage. Adjusting these factors can help maintain optimal performance and prevent failures.

Each bearing system presents unique challenges. Testing and modifying maintenance schedules based on performance data may be necessary. It’s essential to reflect on historic failures to refine your approach.

Step-by-Step Guide to Center Bearing Inspection

Center bearings play a vital role in ensuring smooth vehicle performance. Regular inspection is crucial to identify wear and tear. Start by checking for unusual noises. This could signal issues within the bearing system. According to industry reports, 30% of reported vehicle vibrations stem from worn center bearings. Addressing potential problems early can save significant repair costs.

Next, visually inspect the bearings for any signs of damage. Look for cracks or rust on the outer surface. A simple flashlight can reveal details often missed. Ensure the mounting is secure; loose bolts can contribute to unwanted vibrations. Tools like a dial indicator can measure runout accuracy. Accurate measurements prevent further complications in the drivetrain.

During inspection, grease the bearings as needed. This helps minimize friction and wear. Over-lubricating can be as problematic as under-lubricating. Achieving the right balance is essential for optimal performance. Remember, neglecting these details can lead to costly repairs down the line. A proactive approach allows for better vehicle longevity.

Best Practices for Center Bearing Lubrication and Replacement

Center bearing maintenance is crucial for vehicle performance. Proper lubrication significantly extends the lifespan of the center bearing. Studies show that bearings with consistent lubrication can last up to 30% longer than those without. It is essential to choose the right type of lubricant. Grease consistency and temperature range play a vital role in performance.

When it comes to replacement, timing is everything. A common oversight is delaying replacement until a noticeable failure occurs. This delay can lead to more extensive damage to surrounding components. Regular inspections can mitigate these risks. Look for signs like unusual noises or vibrations. These could indicate that replacement is needed sooner than anticipated.

Additionally, improper installation can lead to failure. Misalignment can stress bearings, causing premature wear. A careful, methodical approach during installation is necessary. Check specifications and tolerances diligently. Investing time in these practices can prevent costly repairs down the line.