Navigating 2025 Trends: How to Choose the Best Plug Valves for Your Industry Needs

As industries evolve and adapt to the emerging trends of 2025, the importance of selecting the right components, such as Plug Valves, becomes paramount. These essential devices play a critical role in regulating flow and managing pressure across various applications, from oil and gas to water treatment. In a world increasingly characterized by precision engineering and high-quality manufacturing, particularly in the context of "精工细造,中国制造,服务世界" (Craftsmanship, China Manufacturing, Serving the World), understanding the nuances of Plug Valves is crucial for making informed decisions. This blog will guide you through the essential factors to consider when choosing Plug Valves tailored to your specific industry needs, ensuring optimal performance and reliability in an ever-changing landscape. Whether you are upgrading existing systems or looking to implement new solutions, this exploration will equip you with the knowledge to navigate the complexities of modern valve selection.

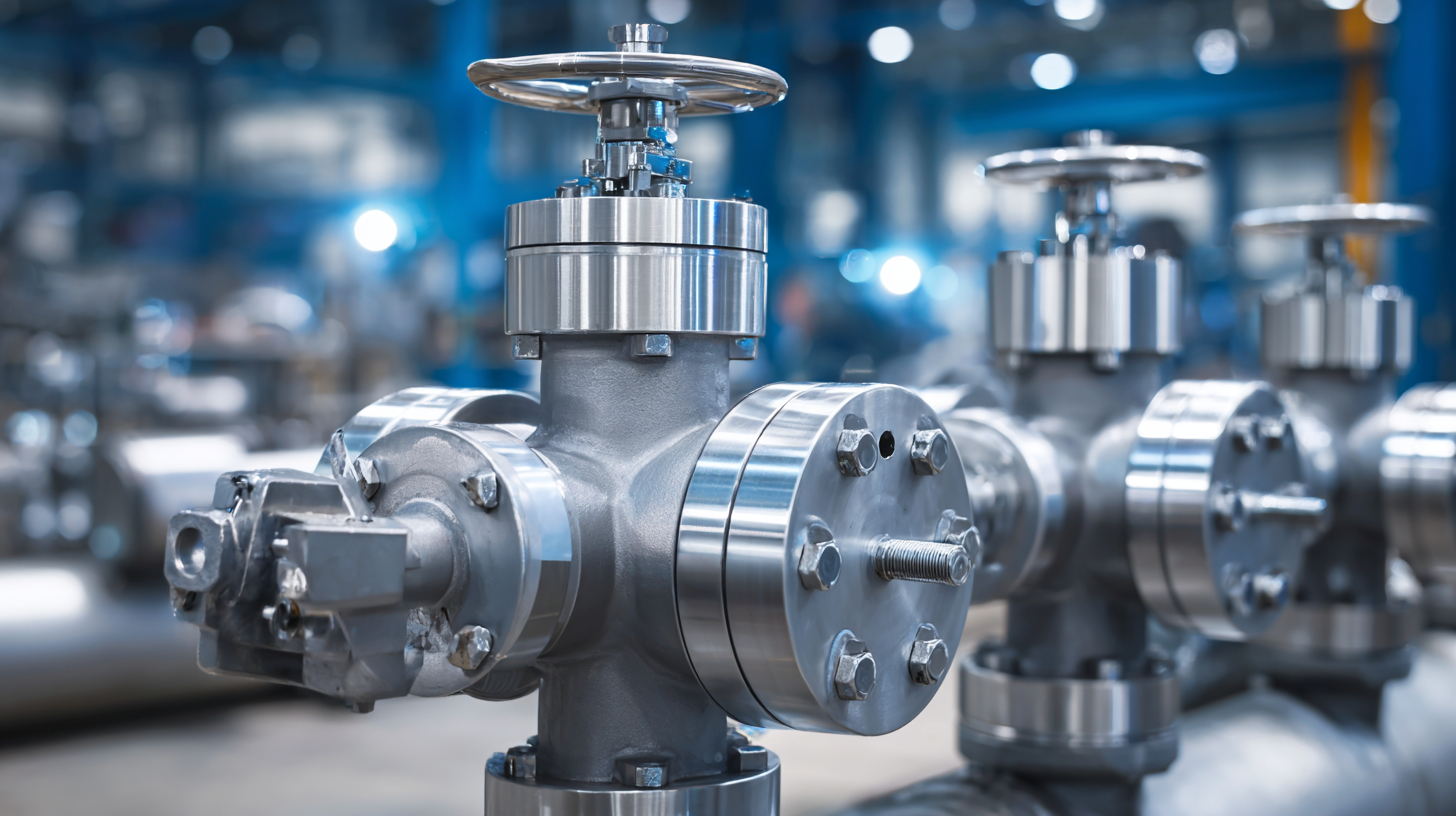

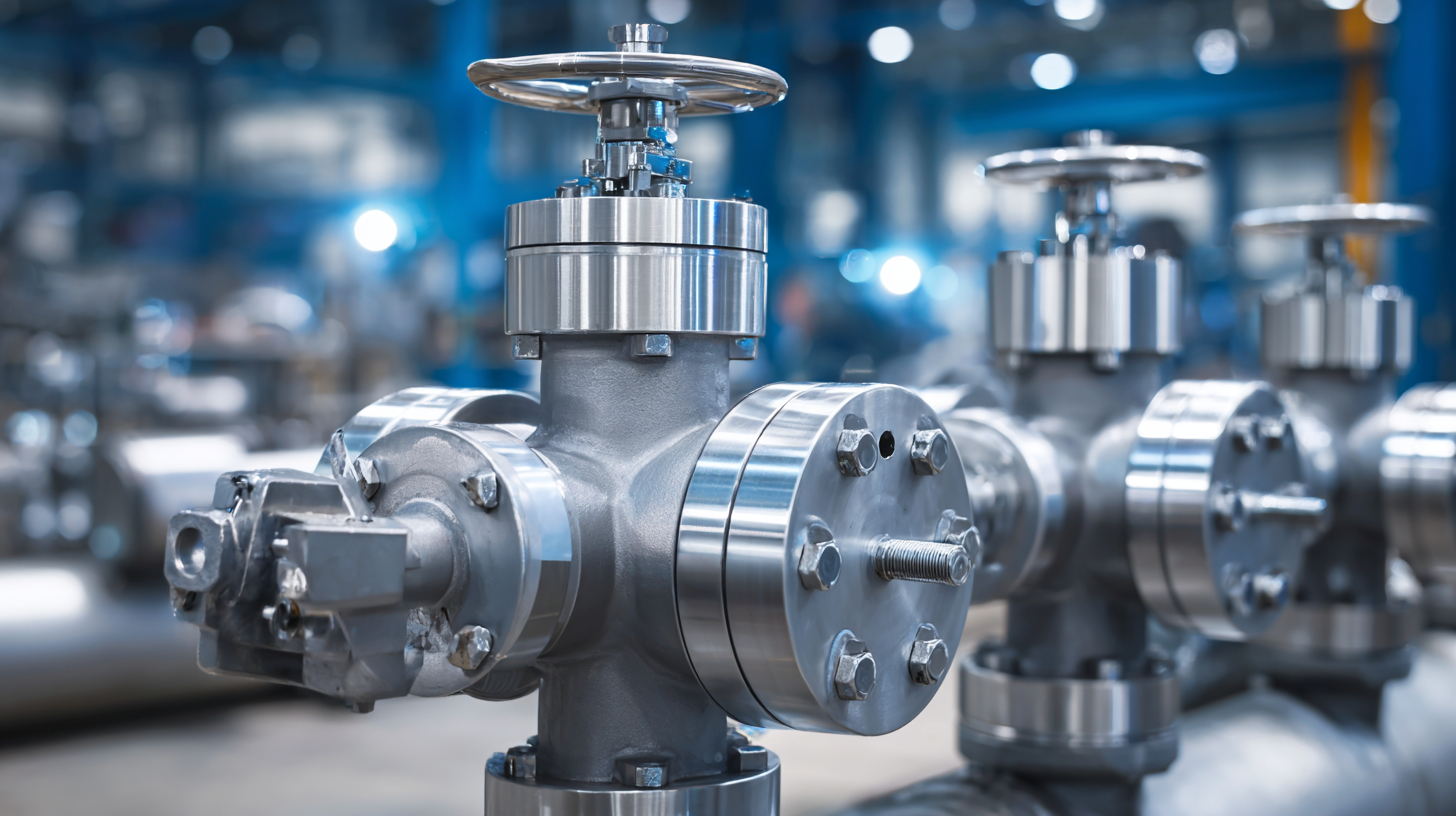

Understanding the Importance of Plug Valves in Various Industries

In the landscape of modern industry, plug valves play a pivotal role across various sectors, offering reliable control over fluid flow. With the global industrial valves market projected to increase from USD 86.67 billion in 2025 to USD 131.6 billion by 2033 at a compound annual growth rate (CAGR) of 6%, understanding the importance of selecting the right plug valve becomes essential for industries aiming to enhance operational efficiency and safety. These valves are particularly beneficial in high-pressure applications due to their robust design and ability to provide a tight seal, reducing the risks of leaks and ensuring environmental compliance.

When choosing the best plug valves for your needs, consider factors such as the specific fluid type, pressure, and temperature conditions. An essential tip is to select valves made from materials compatible with the fluid being transported to prevent corrosion and maintenance issues. Furthermore, customization options are often available to cater to unique application requirements, which can further enhance performance.

Additionally, staying updated with industry forecasts can guide investment decisions. The Middle East industrial valve market, for example, is anticipated to grow at a CAGR of over 6.6% from 2025 to 2034, indicating rising demand and innovation in valve technology. Keeping an eye on such trends can not only improve your operational strategy but also ensure that you are aligned with market advancements.

Key Features to Consider When Selecting Plug Valves

When selecting plug valves for your industry needs, several key features should be prioritized to ensure optimal performance and reliability. Firstly, understanding the maximum operating pressure is crucial. Plug valves are commonly used in high-pressure environments; thus, selecting a valve with the appropriate pressure rating can prevent potential failures and ensure safety. Additionally, the material of the valve is significant: it should withstand the fluid type and operating conditions while maintaining structural integrity over time.

Connection end type is another important feature to consider. Different applications require various connection methods, such as flanged, threaded, or butt-welded, to ensure compatibility with existing piping systems. Furthermore, leakage tolerance is vital, particularly in industries where even minor leaks can lead to significant operational issues or safety hazards. Finally, size availability must align with your specific application requirements. By carefully evaluating these features, you can select the best plug valves that cater to the unique demands of your industry.

Navigating 2025 Trends: Key Features of Plug Valves in Various Industries

This chart illustrates the market demand for plug valves across various industries in 2025. The data reflects thousands of units sold, demonstrating the significant requirements in sectors such as Oil & Gas, Water Treatment, and Chemical Processing. Understanding these trends is essential for making informed decisions when selecting plug valves tailored to specific industrial needs.

Comparing Different Types of Plug Valves for Specific Applications

When it comes to selecting the right plug valves for your industry needs, understanding the specific applications is crucial. Different types of plug valves serve varying purposes, and making an informed choice can enhance operational efficiency. For instance, tapered plug valves are excellent for throttling applications due to their design, which allows for better control of flow rates. On the other hand, lubricated plug valves are suited for applications requiring low operating torque and reduced friction, making them ideal for fluids that may contain particulates.

Tip 1: Always consider the fluid characteristics before selecting a valve type. For corrosive substances, a valve made from resistant materials such as stainless steel is essential to ensure longevity and minimize maintenance costs.

Moreover, the operational environment plays a significant role in the selection process. Non-lubricated plug valves are best for clean services where contamination from lubrication is not an option, while high-temperature applications might benefit from special high-performance plug valves designed to withstand extreme conditions.

Tip 2: Assess the temperature and pressure conditions during valve selection; this will greatly influence the valve material and design choice, ensuring that the valve maintains integrity under operational stresses.

Future Trends in Plug Valve Technology and Innovation

As industries evolve, staying ahead of technological advancements is crucial, particularly when it comes to selecting the right plug valves. In 2025, we can anticipate several trends in plug valve technology that may redefine operational efficiency. Smart plug valves equipped with IoT capabilities will provide real-time data analysis, allowing for proactive maintenance and streamlined operations. Additionally, advancements in materials such as high-performance polymers will enhance durability and resistance to corrosive substances, making them ideal for demanding environments.

Tips: When evaluating plug valves, consider the compatibility of valve materials with the substances they will be handling. Investing in valves with predictive maintenance features can save both time and costs by reducing downtime and unplanned repairs.

Sustainability will also play a determining role in future plug valve design. Manufacturers are increasingly focusing on reducing their environmental impact by optimizing energy consumption and minimizing waste throughout the lifecycle of their products. Such innovations not only comply with regulatory standards but also appeal to eco-conscious consumers.

Tips: Look for manufacturers that prioritize eco-friendly practices, as this can reflect the overall quality and sustainability of their products. Regularly reviewing your operational needs against the latest technological advancements can help you select the best valves that align with both performance and environmental goals.

Best Practices for Maintaining and Optimizing Plug Valve Performance

When it comes to maintaining and optimizing plug valve performance in drinking water distribution systems, understanding the fundamental components is essential. The efficient operation of hydraulic pumps, motors, piping, valves, and end-use equipment hinges on the reliability of plug valves. These valves play a crucial role in controlling fluid flow and can significantly affect the overall efficiency of your pumping system.

Tips for Maintenance:

Regular inspection and maintenance of plug valves are vital to ensure they function optimally. Check for any signs of wear or corrosion and promptly replace components as needed. Additionally, keeping the valve actuator clean and lubricated will help maintain smooth operation and prevent unnecessary downtime.

Optimizing Performance:

To enhance plug valve performance, consider implementing advanced monitoring systems. These systems can provide real-time data on valve operation, allowing for proactive adjustments and maintenance. By leveraging technology, you can optimize flow rates and ensure your drinking water distribution system operates efficiently, ultimately leading to improved service delivery.